Ultimate Guide to Sourcing Flexible Graphite Packing for Optimal Performance and Reliability

In the quest for enhancing performance and reliability in various industrial applications, selecting the right materials is crucial. This is particularly true when it comes to sealing solutions, where Flexible Graphite Packing emerges as a top choice among engineers and procurement specialists. This guide aims to provide a comprehensive overview of sourcing Flexible Graphite Packing, detailing everything from its unique properties and advantages to critical factors for consideration during the procurement process. By understanding the nuances of Flexible Graphite Packing, businesses can ensure they are not only investing in high-quality materials but also optimizing their operational efficiency. Whether you are involved in manufacturing, maintenance, or equipment design, this ultimate guide will equip you with the knowledge needed to navigate the complex landscape of Flexible Graphite Packing, ensuring you make informed decisions that lead to optimal performance in your applications.

Understanding Flexible Graphite Packing: Key Properties and Advantages

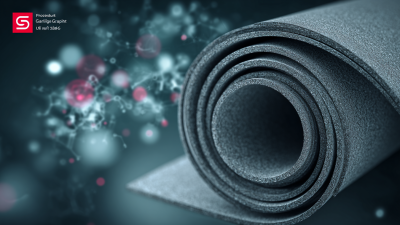

Flexible graphite packing is an essential component in various industrial applications, celebrated for its remarkable properties and advantages. One of the standout characteristics of flexible graphite is its high thermal and chemical resistance. This allows it to maintain performance even in extreme temperatures and corrosive environments, making it ideal for sealing applications in industries such as oil and gas, chemical processing, and power generation. Additionally, its pliability enables it to conform to uneven surfaces, ensuring a tight seal that prevents leaks and enhances reliability.

Flexible graphite packing is an essential component in various industrial applications, celebrated for its remarkable properties and advantages. One of the standout characteristics of flexible graphite is its high thermal and chemical resistance. This allows it to maintain performance even in extreme temperatures and corrosive environments, making it ideal for sealing applications in industries such as oil and gas, chemical processing, and power generation. Additionally, its pliability enables it to conform to uneven surfaces, ensuring a tight seal that prevents leaks and enhances reliability.

Tips: When selecting flexible graphite packing, consider evaluating the temperature range and chemical exposure specific to your application. Always consult with manufacturers about the material composition and its compatibility with your system. Furthermore, proper installation techniques can significantly impact the overall performance and longevity of the packing, so investing in training and resources for your team is crucial.

Another significant advantage of flexible graphite packing is its low friction properties, which reduce wear and extend the service life of equipment. This not only leads to cost savings over time but also minimizes maintenance efforts. The material's excellent compressibility ensures a consistent and effective seal under varying pressure conditions, further enhancing operational reliability.

Tips: Regular inspection and maintenance of the packing can help mitigate potential failures. Consider integrating a routine check-up schedule that aligns with equipment downtime to ensure optimal performance throughout its lifecycle.

Top Industries Benefiting from Flexible Graphite Packing Solutions

Flexible graphite packing has emerged as a crucial component across various industries due to its excellent performance and reliability. As the flexible graphite market is projected to grow to $0.45 billion by 2030, with a steady CAGR of 5.5%, it highlights the increasing demand from key sectors such as oil and gas, automotive, and energy. These industries benefit significantly from the unique properties of flexible graphite, including high thermal resistance, chemical stability, and flexibility, making it an ideal choice for sealing applications and other critical functions.

The top industries leveraging flexible graphite packing solutions include those that require durable and efficient material handling, particularly in high-stress environments. For instance, in the oil and gas sector, the ability to withstand extreme temperatures and pressures is vital for ensuring operational safety and efficiency. Similarly, the automotive industry relies on flexible graphite for gaskets and sealing solutions that enhance engine performance and longevity. As businesses prioritize reliability and performance, the adoption of flexible graphite packing materials is set to play a pivotal role in driving innovation and sustainability within these sectors.

Critical Sourcing Criteria for High-Performance Flexible Graphite Packing

When sourcing flexible graphite packing, it is crucial to establish robust criteria that ensure optimal performance and reliability. One critical factor to consider is the purity of the graphite material. High-purity graphite minimizes the risk of contamination and enhances sealing efficiency, making it essential for applications in high-temperature environments or where chemical resistance is paramount. Sourcing from reputable suppliers who provide detailed specifications and performance data can greatly influence the reliability of the packing.

Another important criterion is the physical characteristics of the graphite packing itself. The thickness, density, and compressibility of the packing materials directly affect their performance under different operational conditions. For instance, choosing packing with the right density can lead to better sealing and longevity in high-pressure systems. Additionally, understanding the temperature tolerance and chemical compatibility of the graphite packing is vital, particularly for industries such as petrochemical and power generation, where exposure to extreme conditions is common. Careful evaluation of these sourcing criteria will ensure you select the most suitable flexible graphite packing for your specific applications.

Performance Metrics of Flexible Graphite Packing

Cost Analysis: Investing in Quality Flexible Graphite Packing for Long-Term Reliability

In today's rapidly evolving manufacturing landscape, companies must prioritize the sourcing of high-quality materials to enhance both performance and reliability. Investing in quality flexible graphite packing is increasingly recognized as a crucial aspect for ensuring long-term operational efficiency, particularly in sectors like battery production. A recent report highlights that as global battery production is anticipated to increase significantly, the market for critical components such as flexible graphite packing is poised for expansion. Specifically, the demand for battery cell components, which are essential for the manufacturing of lithium-ion batteries, is projected to grow by 19 percent in the coming years.

Moreover, as manufacturers navigate the complexities of producing high-quality batteries at scale, understanding the cost dynamics associated with component sourcing becomes essential. The detailed insights from industry reports indicate that optimal setup costs for production plants can lead to improved return on investment (ROI). Companies focusing on advanced manufacturing techniques and sustainability will also find it beneficial to invest in quality components, which not only enhance product reliability but also align with the broader goals of transport decarbonization and operational efficiency. This dual focus on cost management and the strategic investment in quality materials like flexible graphite packing positions manufacturers to thrive in a competitive and environmentally-conscious market.

Expert Tips for Evaluating and Selecting Flexible Graphite Packing Suppliers

When it comes to sourcing flexible graphite packing, evaluating suppliers is pivotal to ensure optimal performance and reliability. Start by assessing the supplier’s experience in the industry. A provider with a long-standing reputation is often equipped with the knowledge needed to address unique challenges and offer solutions that enhance product performance. Look for suppliers who specialize in flexible graphite materials, as their expertise can translate into better product quality and more tailored customer support.

Another crucial aspect is the supplier's commitment to quality control and certifications. Check if they adhere to industry standards such as ISO 9001, which ensures consistent quality management. Inquire about their manufacturing processes and whether they conduct regular testing to verify the integrity of their products. It’s also beneficial to request customer testimonials or case studies that demonstrate the performance of their graphite packing in real-world applications. By focusing on these factors, you can ensure that the supplier you choose will provide flexible graphite packing that meets your operational needs and enhances the overall reliability of your applications.

Related Posts

-

Real-World Applications of the Best Graphite Gasket Sheet in Various Industries

-

Exploring Innovative Alternatives to Graphite Gasket Sheets for Diverse Applications

-

5 Essential Tips for Choosing Graphite Paper Officeworks for Your Business Needs

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications

-

Exploring Future Innovations in Best Flexible Graphite Gasket Technology for 2025

-

7 Best Reasons to Choose Graphite Wall Paper for Your Next Renovation