2025 Guide: How to Choose the Best Thermal Graphite Sheet for Your Application

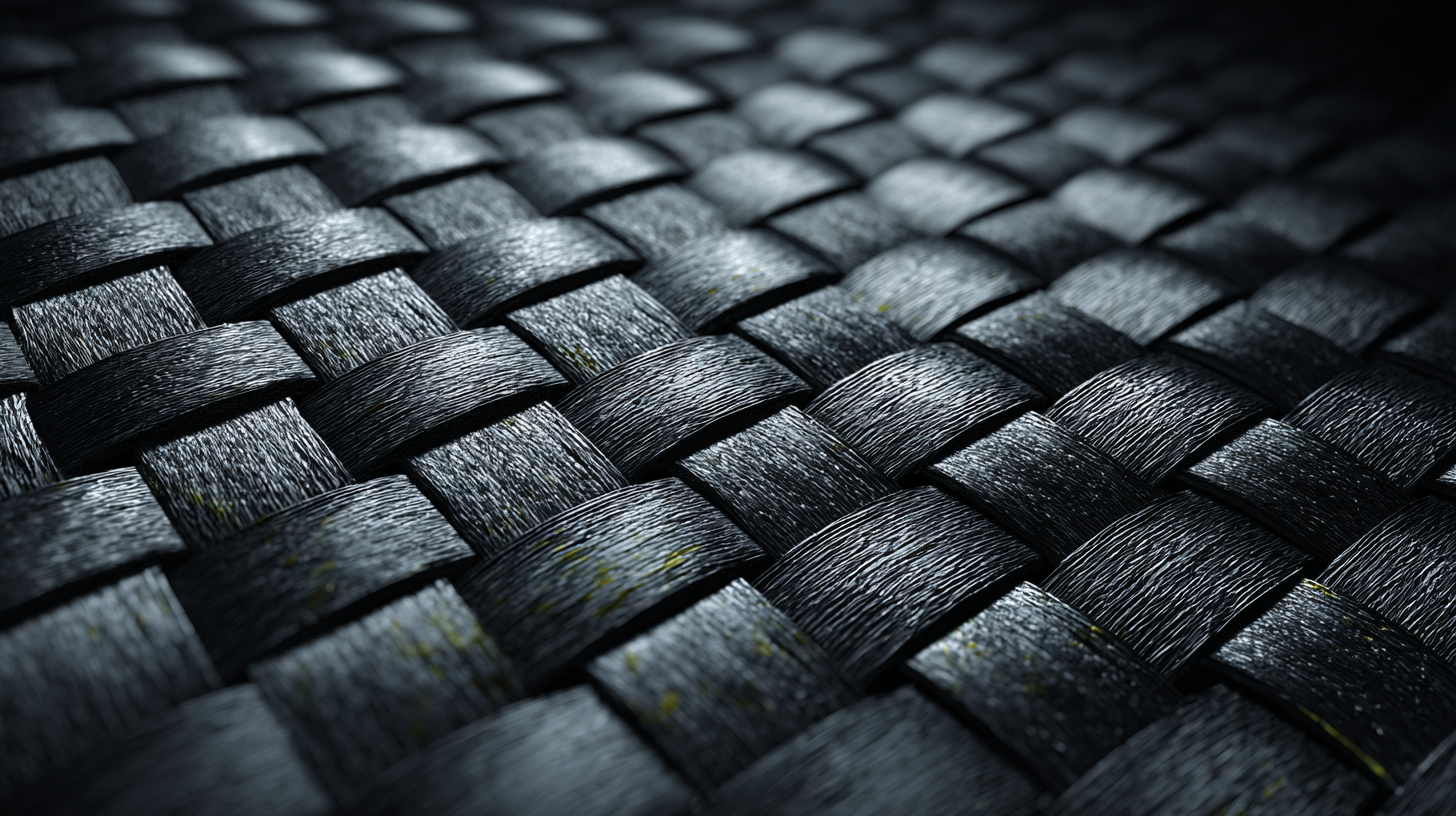

In recent years, the demand for high-performance thermal management solutions has surged, primarily driven by advancements in electronics and the automotive industry. According to a recent industry report, the global thermal management materials market is expected to grow significantly, reaching approximately $22 billion by 2025, with thermal graphite sheets playing a pivotal role in this expansion. Thermal graphite sheets are renowned for their exceptional thermal conductivity, lightweight properties, and flexibility, making them ideal for various applications, from consumer electronics to high-end industrial machinery.

As companies prioritize efficiency and performance in their products, choosing the right thermal management materials becomes critical. The unique properties of thermal graphite sheets, including their ability to dissipate heat effectively while maintaining structural integrity, enable engineers to design more compact and efficient devices. With numerous options available, understanding the key factors that differentiate thermal graphite sheets is essential for OEMs and manufacturers seeking to optimize their applications. This guide will explore the top five thermal graphite sheets available in 2025, offering insights into selecting the best material tailored to specific operational needs, ultimately enhancing product performance and reliability.

Key Characteristics to Consider When Selecting Thermal Graphite Sheets

When selecting the best thermal graphite sheet for your application, it is essential to consider several key characteristics that directly impact performance. Thermal conductivity is perhaps the most significant attribute; high-performance sheets typically exhibit a thermal conductivity exceeding 1500 W/mK. According to a report by the Global Graphite Market Insights, the demand for thermally conductive materials is projected to grow at a CAGR of 6.5% through 2025, driven by advancements in electronics and thermal management solutions.

Another critical factor is the thickness of the thermal graphite sheet. Sheets ranging from 0.5 mm to 3.0 mm are commonly available, and the thickness can affect both flexibility and thermal performance. Additionally, the compressibility and hardness of the material play a vital role in its ability to conform to uneven surfaces and maintain contact under varying pressure conditions. A study published in the Journal of Thermal Analysis has shown that optimal compressibility can enhance thermal interface performance by nearly 30%, making it crucial for applications in high-density electronic devices.

Furthermore, you should consider the thermal resistance and the form factor of the graphite sheet. Lower thermal resistance values ensure better heat dissipation, which is particularly vital in high-performance computing applications. The choice of adhesive backing can also influence the ease of installation and the integrity of the thermal pathway. By taking these characteristics into account, you can better ensure that you select the optimal thermal graphite sheet for your specific needs.

Comparative Analysis of the Top 10 Thermal Graphite Sheets in 2025

As the flexible graphite market continues to evolve, it is projected to grow from USD 0.35 billion in 2025 to USD 0.45 billion by 2030, with a compound annual growth rate (CAGR) of 5.5%. This growth highlights the increasing demand for thermal interface materials (TIMs) across various applications, especially in sectors like electric vehicles and power electronics. In particular, the upcoming report on Thermal Interface Materials for 2026-2036 projects significant advancements in TIM technologies, which are crucial for optimizing heat dissipation in high-performance electronic components.

A comparative analysis of the top thermal graphite sheets in 2025 will reveal their performance in terms of thermal conductivity, flexibility, and thickness. The study of thermal interface materials, including variations like TIM1 and TIM2, is essential for understanding their roles in boosting the efficiency and reliability of modern electronic devices. With the growing emphasis on thermal management in data centers and 5G technology, selecting the right thermal graphite sheet can significantly impact overall system performance and longevity.

Application-Specific Recommendations for Optimal Thermal Management

When selecting a thermal graphite sheet for your specific application, understanding the unique thermal management requirements of different industries is crucial. For instance, in the electronics sector, where heat dissipation is paramount, a thermal conductivity of at least 1500 W/m·K is often recommended. According to a recent market report by Research and Markets, the demand for effective thermal management solutions in electronics is projected to increase by 10% annually as devices become smaller and more powerful.

In applications such as automotive engineering, the need for thermal graphite sheets extends beyond conductivity to include durability and resistance to thermal cycling. Reports from Frost & Sullivan highlight that automotive manufacturers are increasingly integrating thermal management materials with a thermal conductivity of up to 1800 W/m·K in their designs to optimize heat distribution and enhance component longevity. Selecting a sheet that meets specific thermal performance metrics, like low thermal resistance and high compressibility, is essential for ensuring efficiency in high-temperature environments.

Moreover, industries such as renewable energy and aerospace often require customized solutions tailored to extreme conditions. Data from Statista indicate that thermal management products tailored for renewable applications are seeing a significant growth rate, with an annual increase of 15% forecasted. By referencing these application-specific recommendations, engineers and procurement specialists can make informed decisions when choosing thermal graphite sheets, ensuring optimal performance tailored to their unique operational requirements.

Evaluating Cost vs. Performance for Thermal Graphite Sheets

When selecting a thermal graphite sheet, it's essential to strike a balance between cost and performance. High-performance sheets may offer superior thermal conductivity and durability, but they often come with a hefty price tag. Conversely, more affordable options might not provide the necessary thermal management for critical applications. Therefore, understanding the specific requirements of your project is crucial in making an informed decision.

**Tips:** Consider your application’s thermal requirements: If cooling efficiency is paramount, investing in a higher-quality sheet could save you money in the long run by enhancing performance and reliability. Additionally, evaluate the overall cost of ownership, including installation and potential maintenance costs, rather than just the upfront investment.

Also, keep in mind the type of environment your thermal graphite sheet will be exposed to. Some applications demand sheets that can withstand extreme temperatures or harsh chemicals, making it necessary to weigh these factors against initial costs to ensure long-term performance efficiently matches your budget. Always prototype with a few options to determine which sheet delivers the best performance relative to its cost.

2025 Guide: Evaluating Cost vs. Performance for Thermal Graphite Sheets

Future Trends in Thermal Graphite Sheet Technology and Innovation

As the demand for advanced thermal management solutions grows, the thermal graphite sheet technology is evolving rapidly. Future trends suggest a shift towards enhanced thermal conductivity and flexibility, catering to the needs of diverse applications from electronics cooling to automotive industries. Innovations such as the integration of nano-materials may further improve performance, providing efficient heat dissipation in compact designs.

**Tips:** When selecting a thermal graphite sheet, consider the specific thermal conductivity requirements of your application. Assess the operating temperature range as well; different materials are better suited for high-heat environments. Additionally, the thickness of the sheet can affect performance, so choose wisely based on your spatial constraints and thermal management needs.

Looking ahead, manufacturers are likely to emphasize sustainability, developing eco-friendly production processes and materials. This aligns with global trends towards greener technology solutions. Users should watch for advancements that may not only improve performance but also reduce environmental impact in the production and lifecycle of thermal graphite sheets.

2025 Guide: How to Choose the Best Thermal Graphite Sheet for Your Application

| Property | Value (Typical) | Application Suitability | Future Trends |

|---|---|---|---|

| Thermal Conductivity | Above 1500 W/m·K | High-performance electronics | Increased efficiency in thermal management |

| Thickness | 0.5 mm - 3 mm | Compact devices, LED applications | Variety for custom applications |

| Thermal Resistance | < 0.10 °C·in²/W | Power electronics | Lower resistance through innovative materials |

| Flexibility | High | Portable and wearable devices | Advancements in ultra-thin materials |

| Application Temperature | -40°C to +200°C | Automotive, industrial | Higher tolerance materials for extreme conditions |

Related Posts

-

Mastering Graphite Thermal Film Application in Your Projects a Step by Step Guide

-

Unlocking the Benefits: How Natural Flake Fuels the Future of Sustainable Packaging

-

Global Market Trends and Insights for Best Graphite Paper by 2025 with Real World Applications

-

Top 5 Benefits of Using Flexible Graphite Gaskets for Industrial Applications

-

Understanding the Advantages of Flexible Graphite Sheet in High Temperature Applications

-

Innovative Applications of Flexible Graphite Sheet in High Performance Industries