Why Use Graphite Insulating Lining Paper for Improved Thermal Efficiency

In recent years, the pursuit of improved thermal efficiency across various industrial applications has led to the exploration of advanced materials, notably the adoption of Graphite Insulating Lining Paper. As energy costs continue to rise, industries have begun to prioritize not only the performance efficiency of their operations but also sustainable practices that can contribute to long-term savings. According to a report from the International Energy Agency (IEA), improving thermal insulation can yield energy savings of up to 30% in industrial processes, underscoring the need for effective insulating materials.

Graphite Insulating Lining Paper stands out in this context due to its unique properties that enhance thermal performance. Research indicates that materials incorporating graphite can significantly reduce thermal conductivity compared to conventional insulation solutions, which can lead to more stable operating conditions and reduced energy consumption. Furthermore, a study published in the Journal of Thermal Science reported that the application of innovative insulating materials, including graphite-based composites, has the potential to improve overall system efficiency by as much as 25%, benefiting both the environment and operational costs.

As industries confront the dual challenges of rising operational costs and increasing environmental regulations, the integration of Graphite Insulating Lining Paper presents a viable solution for enhancing thermal efficiency. The advancements in this field align with a growing trend towards adopting high-performance insulation materials, supporting a more sustainable and cost-effective approach to energy management.

Benefits of Graphite Insulating Lining Paper in Energy Efficiency

Graphite insulating lining paper has emerged as a significant player in enhancing energy efficiency, particularly in industrial environments where thermal management is critical. According to a report by the International Energy Agency (IEA), inefficient heat retention can result in energy losses of up to 20% in various applications. By utilizing graphite insulating lining paper, industries can substantially reduce these losses. The unique properties of graphite, which boasts a thermal conductivity that minimizes heat transfer while offering excellent insulation, make it a superior choice for facilities aiming to optimize their thermal efficiency.

Furthermore, studies have shown that the application of graphite insulating materials can lead to a reduction in energy costs by up to 30%. This remarkable improvement is primarily attributed to graphite’s ability to maintain temperature stability, which enhances process reliability and reduces the need for excessive energy consumption. An independent analysis from a leading energy efficiency consultancy found that retrofitting with graphite lining paper can lead not only to direct energy savings but also to reduced wear and tear on equipment, ultimately leading to lower maintenance costs over time. The integration of such materials is not only a step towards sustainability but also a sound financial investment for companies committed to energy efficiency.

Thermal Efficiency Improvement with Graphite Insulating Lining Paper

Thermal Conductivity Properties of Graphite Compared to Traditional Insulation

Graphite insulating lining paper has garnered attention for its exceptional thermal conductivity properties, setting it apart from traditional insulation materials. Specifically, graphite exhibits thermal conductivity ranging from 150 to 200 W/m·K, which is substantially higher than that of fiberglass, typically around 0.04 W/m·K. This significant difference means that graphite can effectively transfer heat, reducing temperature differentials and promoting uniform heat distribution. For industrial applications, the heightened efficiency can lead to substantial energy savings, reducing operational costs and carbon footprints.

Incorporating graphite insulation into building designs and industrial processes can enhance energy performance considerably. A report by the International Energy Agency indicates that improved insulation can lead to energy savings of 20-30%, showcasing the potential impact of superior materials like graphite. Moreover, due to its lightweight nature and flexibility, graphite lining paper can be easily integrated into existing structures, offering a practical solution for retrofitting older insulation systems.

Tips: When considering insulation options, prioritize materials with high thermal conductivity to maximize energy efficiency. It's also beneficial to assess the overall lifecycle costs, as investments in superior insulation like graphite can yield savings over time. Additionally, consult with experts in thermal management to tailor insulation solutions that meet specific operational needs.

Why Use Graphite Insulating Lining Paper for Improved Thermal Efficiency

| Insulation Type | Thermal Conductivity (W/m·K) | Thermal Resistance (m²·K/W) | Application Temperature Range (°C) | Weight (kg/m²) |

|---|---|---|---|---|

| Graphite Insulating Lining Paper | 0.15 | 6.67 | -50 to 300 | 1.0 |

| Polyurethane Foam | 0.025 | 40.0 | -50 to 100 | 2.0 |

| Fiberglass Insulation | 0.04 | 25.0 | -20 to 200 | 3.5 |

| Mineral Wool Insulation | 0.045 | 22.2 | -50 to 700 | 4.0 |

Applications of Graphite Insulation in Industrial and Residential Settings

In both industrial and residential settings, the application of graphite insulating lining paper has been recognized for its exceptional thermal efficiency. Industries such as manufacturing and energy production are increasingly opting for graphite-based insulation materials due to their ability to withstand high temperatures while minimizing heat loss. According to a report by the International Journal of Thermal Science, graphite insulation can reduce thermal conductivity by over 30% compared to traditional materials, leading to significant energy savings and enhanced operational efficiency.

In residential applications, the use of graphite insulation extends beyond mere energy savings; it also contributes to improved indoor comfort. The National Association of Home Builders highlights that homes insulated with materials that include graphite composites experience reduced energy bills by approximately 15-20% annually. This is particularly beneficial in regions with extreme climates, where maintaining consistent indoor temperatures can be a challenge. By integrating graphite insulating lining paper into walls, attics, and roofs, homeowners not only boost their energy efficiency but also add a layer of fire resistance and noise reduction, making their living spaces safer and more tranquil. As awareness of sustainable practices grows, the adoption of graphite insulation is likely to become more prevalent across various sectors.

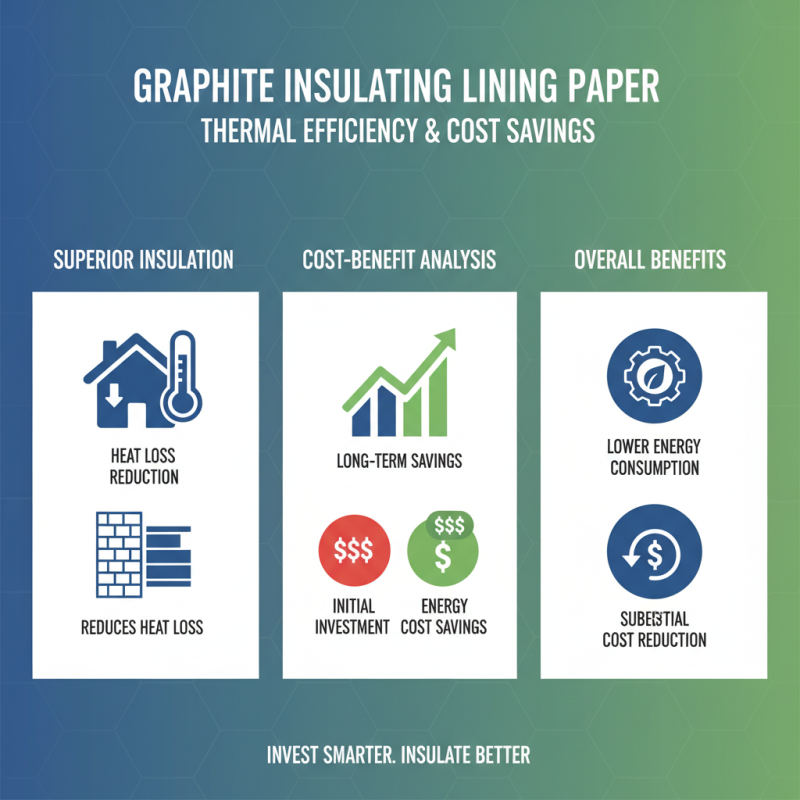

Cost-Benefit Analysis of Using Graphite Insulating Lining Paper

The use of graphite insulating lining paper is becoming increasingly popular due to its significant thermal efficiency benefits. Conducting a cost-benefit analysis reveals that while the initial investment may seem higher than standard insulation materials, the long-term savings in energy costs can outweigh those expenses substantially. Graphite lining paper provides superior insulation, reducing heat loss in industrial applications, thereby lowering the overall energy consumption and costs.

One important factor to consider is the lifespan of graphite insulating lining paper. Unlike conventional insulation materials that may require replacement throughout their lifecycle, graphite-infused options tend to have a longer durability. This longevity means less frequent upgrades or replacements, contributing to further savings. Furthermore, the enhanced thermal regulation provided by graphite helps maintain optimal operating temperatures, which can lead to increased productivity in industrial processes.

Tips: When considering insulation materials, it’s essential to evaluate not just the initial costs but also the long-term performance and savings potential. Additionally, always factor in installation and maintenance requirements to get a comprehensive view of the total cost. By prioritizing energy efficiency and durability, facilities can make more informed decisions that ultimately lead to better financial outcomes.

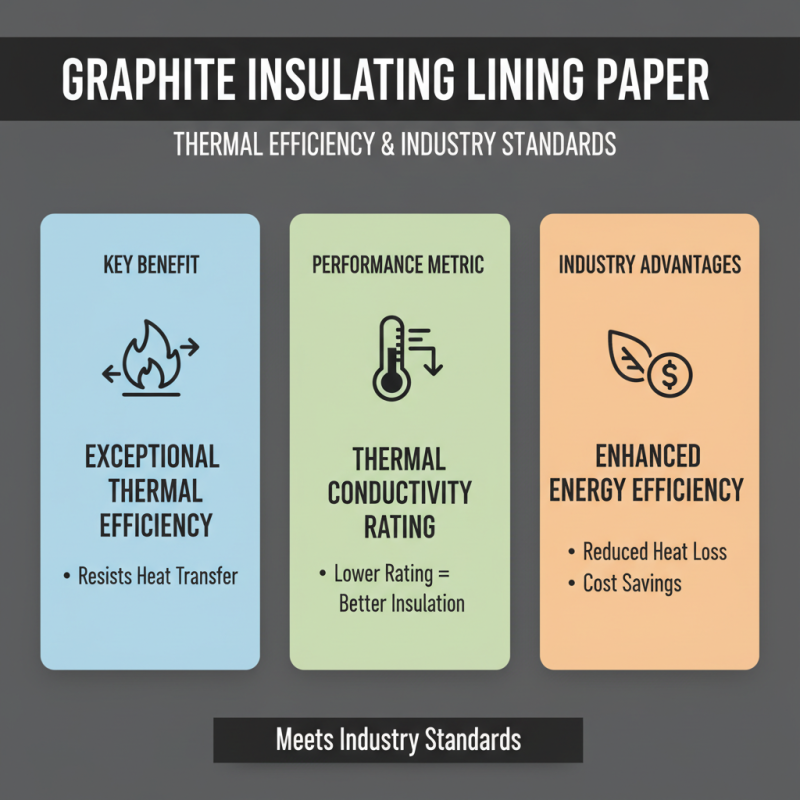

Industry Standards and Performance Metrics for Graphite Insulation Products

Graphite insulating lining paper has gained recognition in various industries for its exceptional thermal efficiency. The effectiveness of these insulation products is often measured against specific industry standards that dictate performance metrics. One such standard is the thermal conductivity rating, which gauges how well the material can resist heat transfer. Products with lower thermal conductivity ratings are preferred, as they indicate improved insulation capabilities, ultimately leading to enhanced energy efficiency and cost savings for operations.

In addition to thermal conductivity, other performance metrics include tensile strength, moisture resistance, and chemical stability. These characteristics ensure that the graphite insulation not only performs well thermally but also withstands potentially harsh environmental conditions. Compliance with established industry standards, such as ASTM International or ISO guidelines, further enhances the credibility and reliability of graphite insulation products. This adherence not only assures manufacturers of the product's quality but also gives consumers confidence in the insulation's long-term performance and durability.

Related Posts

-

7 Essential Tips for Choosing the Right Graphite Insulating Lining Paper

-

Top Strategies for Sourcing the Best Graphite Natural in the Industry

-

5 Essential Tips for Choosing the Right Flexible Graphite Gasket for Your Applications

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications

-

China's Leading Edge: The Evolution of the Best Graphite Thermal Sheets in Global Manufacturing

-

Innovative Applications of Graphite Thermal Film in Modern Electronics