What is Graphite Insulating Lining Paper and Its Uses?

Graphite Insulating Lining Paper is a crucial material widely used in various industries. This unique paper offers excellent thermal and electrical insulation properties. Dr. Emily Chen, a leading expert in advanced materials, states, "Graphite Insulating Lining Paper has transformed the way we approach thermal management in high-performance applications."

The applications of this product are diverse. Industries such as aerospace, electronics, and automotive rely on Graphite Insulating Lining Paper to enhance efficiency. Its lightweight and durable nature make it an ideal choice. Furthermore, this material can prevent overheating and improve safety in sensitive equipment.

Despite its advantages, challenges exist. The production process can be complex and costly. Not all manufacturers meet high-quality standards. It's essential for companies to invest in reliable suppliers. Ultimately, understanding the uses and limitations of Graphite Insulating Lining Paper is vital for innovation in various fields. This material not only serves practical purposes but also invites ongoing exploration and refinement.

What is Graphite Insulating Lining Paper?

Graphite insulating lining paper is an innovative material in the realm of thermal insulation. Its core component, graphite, offers outstanding heat resistance. This makes it suitable for high-temperature applications. The unique structure of graphite allows it to reflect thermal radiation effectively. Reports indicate that materials like graphite can withstand temperatures exceeding 3000°C. This property is crucial across many industries.

In industries such as metallurgy and ceramics, the use of graphite insulating lining paper has surged. It is often deployed in furnaces and kilns to enhance energy efficiency. Data shows that using high-quality insulation can reduce energy consumption by up to 30%. However, the cost implications can be significant, leading some companies to opt for cheaper alternatives that may not perform as well. While the benefits are clear, organizations must weigh cost versus efficiency.

Application in the aerospace industry is also noteworthy. Here, graphite insulating paper helps protect sensitive components from heat damage. Nevertheless, the challenge lies in sourcing materials that meet stringent quality standards. The inconsistency in raw materials can lead to subpar performance, which raises questions about reliability. The landscape for graphite insulating lining paper is evolving, but issues with quality assurance remain an area to watch.

Graphite Insulating Lining Paper Uses and Applications

Composition and Properties of Graphite Insulating Lining Paper

Graphite insulating lining paper is composed primarily of graphite particles, which are bonded together with a polymer matrix. This unique composition results in exceptional thermal stability and resistance to electrical conductivity. According to industry reports, the thermal conductivity of graphite materials can reach 600 W/m·K, making it suitable for high-temperature applications.

The properties of graphite insulating lining paper also include lightweight and flexibility. This allows for easier installation in various setups, from industrial machinery to electronic devices. The material is typically rated for temperatures as high as 2000 degrees Celsius in inert atmospheres. Moreover, it's worth noting that while this paper excels in resistance to thermal shock, its mechanical strength can be a limitation in certain applications, requiring users to carefully assess their requirements.

In addition to heat applications, graphite insulating lining paper finds use in soundproofing due to its density. Studies show that it can reduce sound transmission by over 20 dB in some configurations. While such properties are beneficial, achieving optimal performance often demands precision in production and installation. Minor imperfections in thickness or alignment can drastically impact effectiveness, leading to unsatisfactory results in demanding environments.

Applications of Graphite Insulating Lining Paper in Industries

Graphite insulating lining paper serves multiple industries with its unique properties. This material exhibits exceptional thermal resistance, effectively shielding machinery from intense heat. According to a 2022 market report, the global demand for insulating materials is expected to reach $86 billion by 2027. This highlights the growing reliance on products like graphite lining paper.

In manufacturing, graphite insulating lining paper is commonly used in furnaces and kilns. A recent analysis indicated that more than 45% of industrial thermal applications incorporate this material. Its ability to withstand high temperatures without degrading is crucial. Moreover, the paper's lightweight properties facilitate easy installation in complex machinery.

However, not all applications may maximize its potential. Some industries may overlook necessary ventilation, leading to inefficiencies. While the thermal management role is understood, there is still room for improvement in its applications. Overall, graphite insulating lining paper represents a significant yet often underutilized resource across various sectors.

Advantages of Using Graphite Insulating Lining Paper

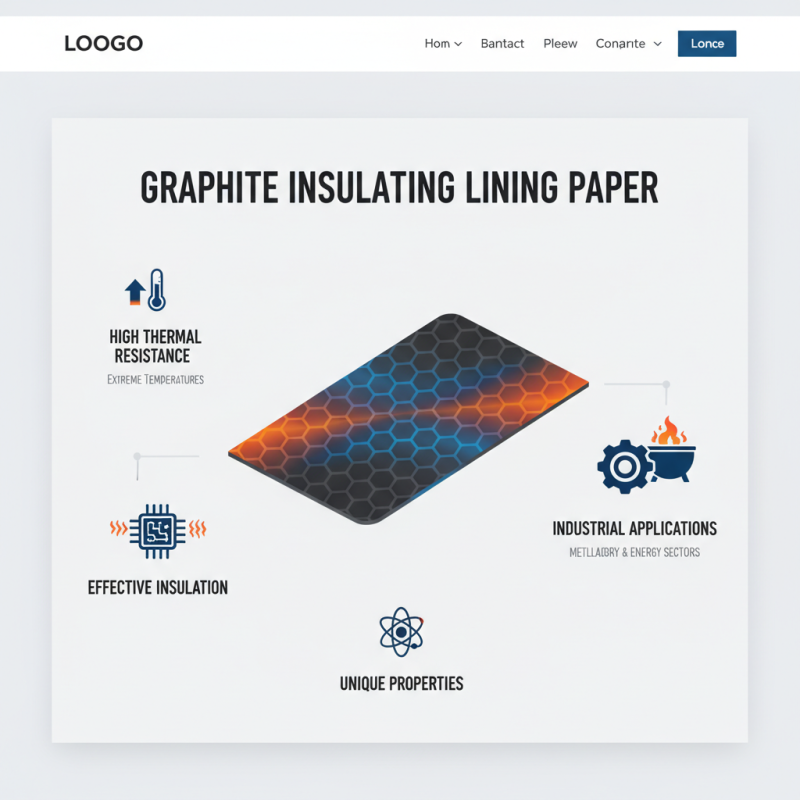

Graphite insulating lining paper is a specialized material that offers excellent thermal resistance. Its unique properties make it an ideal choice for a variety of applications. One of the key advantages is its high thermal conductivity. It can handle extreme temperatures while providing effective insulation. This feature is essential in industrial processes, particularly in metallurgy and energy sectors.

Another significant benefit is its lightweight nature. Traditional materials can be heavy and cumbersome. Graphite insulating lining paper, on the other hand, is easier to handle. This can lead to reduced transportation costs. According to industry reports, up to 20% of total operational costs can be saved by switching to lighter materials. Companies are increasingly looking for ways to cut down expenses without compromising quality.

Tips: Always ensure that the installation is done properly. Improper installation can lead to performance issues. Additionally, keep in mind that while graphite paper is durable, it does require regular checks. Some users report wear over time. Regular maintenance can help extend its lifespan and ensure operational efficiency.

Installation and Maintenance Guidelines for Graphite Insulating Lining Paper

Graphite insulating lining paper is a versatile material known for its thermal and electrical insulation properties. Proper installation is crucial for optimal performance. Start by ensuring that the surface is clean and dry. Any dirt or moisture can weaken adhesion. Use a sharp utility knife for precise cuts. This helps prevent damage to the lining paper, which can undermine insulation effectiveness.

During installation, apply pressure gradually. Work from one end to the other. This step minimizes air bubbles and ensures a tight fit. If you encounter bubbles, use a roller to gently push them out. Regular checks after installation are advisable. Look for signs of wear or peeling. Small repairs, if caught early, can extend the lifespan of the lining.

Maintenance involves periodic inspections and cleaning. Use a soft cloth to wipe down surfaces. Avoid harsh chemicals that could degrade the material. It’s important to reflect on your installation technique. If problems arise, consider revisiting your methods. Each project can reveal new insights into improving your skills.

Related Posts

-

Top 10 Benefits of Using Natural Graphite Sheet for Your Applications

-

The Ultimate Guide to Sourcing the Best Natural Graphite: Insights and Trends for Global Buyers

-

7 Essential Tips for Choosing the Perfect Graphite Gasket Sheet for Your Needs

-

Unlocking Superior Performance with Best Flexible Graphite Sheets from Leading Chinese Manufacturers

-

Overcoming the Challenges of Using Best Graphite Paper Officeworks in Your Projects

-

2025 Guide: How to Choose the Best Thermal Graphite Sheet for Your Application