Why Choose Flexible Graphite Sheet for Your Gasket and Sealing Needs

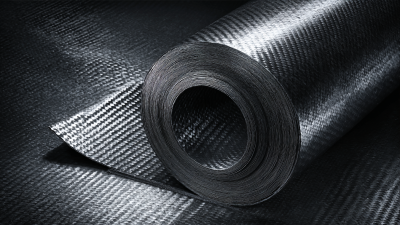

When it comes to selecting materials for gaskets and sealing applications, one option has gained significant attention: the Flexible Graphite Sheet. Known for its exceptional properties, this material is increasingly favored across various industries for its versatility and reliability. Unlike traditional sealing materials, flexible graphite offers superior resistance to high temperatures, chemicals, and mechanical wear, making it an ideal choice for demanding environments.

Flexible Graphite Sheets can be engineered to meet specific requirements, providing tailored solutions for diverse sealing challenges. Their unique structure allows for effective sealing in applications involving high pressure and fluctuation, enhancing operational efficiency. Moreover, the ease of installation and maintenance associated with flexible graphite further underscores its appeal in industrial applications.

As businesses strive for improved performance and reduced downtime, the advantages of Flexible Graphite Sheets become evident. This material not only fulfills sealing needs but also contributes to the longevity and reliability of machinery, reinforcing its status as a go-to choice for gasket applications.

Understanding Flexible Graphite Sheet: A Comprehensive Overview

Flexible graphite sheets have gained recognition in various industries due to their remarkable properties that make them ideal for gasket and sealing applications. Composed primarily of high-purity natural graphite, these sheets exhibit excellent thermal and chemical resistance. According to a market research report by IMARC Group, the flexible graphite market is projected to grow significantly, driven by its increasing adoption in automotive and industrial sectors. The intrinsic characteristics of flexible graphite, such as high compressibility and adaptability to uneven surfaces, contribute to its widespread use in demanding applications.

When choosing flexible graphite sheets, it is essential to consider the material's thickness and density, which can impact sealing performance. A thicker sheet provides better sealing capabilities but may require more compression for effective sealing. Moreover, the low surface roughness of flexible graphite maximizes the contact area, enhancing the sealing effectiveness further.

**Tips**: Always evaluate the temperature and pressure conditions of the application to select the appropriate grade of flexible graphite. Additionally, ensure that the installation surface is clean and free from contaminants to guarantee optimal sealing performance. Engaging with suppliers who provide detailed technical data can also aid in making informed decisions tailored to specific sealing needs.

Key Properties of Flexible Graphite Sheets for Gasket Applications

Flexible graphite sheets have gained popularity in gasket applications due to their unique properties that cater specifically to sealing requirements. One of the standout characteristics of these sheets is their excellent thermal conductivity. This property allows them to withstand high temperatures while maintaining their integrity, making them suitable for environments prone to heat fluctuations. Additionally, the ability of flexible graphite to resist oxidation enhances its durability, ensuring long-lasting performance in demanding industrial settings.

Another critical property of flexible graphite sheets is their chemical resistance. They provide exceptional resistance to a wide range of chemicals, including acids, bases, and solvents. This versatility makes them an ideal choice for gaskets in various applications, from automotive to chemical processing industries. Furthermore, flexible graphite sheets exhibit excellent compressibility and recovery, allowing them to create effective seals even under varying pressure conditions. This adaptability ensures a tight seal, minimizing the risk of leakage and enhancing overall system efficiency.

Why Choose Flexible Graphite Sheet for Your Gasket and Sealing Needs - Key Properties of Flexible Graphite Sheets for Gasket Applications

| Property | Description | Benefits for Gasket Applications |

|---|---|---|

| Thermal Conductivity | Excellent thermal conductivity due to the structure of graphite. | Efficient heat dissipation in high-temperature applications. |

| Chemical Resistance | Resistant to a wide range of chemicals and solvents. | Long-lasting performance in harsh environments. |

| Flexibility | High degree of flexibility allows for easy compression. | Ensures a tight seal even in irregular surfaces. |

| Temperature Resistance | Can withstand extreme temperatures (up to 480°C or 900°F). | Ideal for high-heat applications like engines and reactors. |

| Compressibility | Good compressibility performance under various pressures. | Effective in creating seals over time without losing integrity. |

Comparative Analysis: Flexible Graphite vs. Traditional Gasket Materials

When selecting materials for gaskets and seals, the choice between flexible graphite and traditional options such as rubber or cork becomes crucial. Flexible graphite sheets stand out due to their exceptional thermal and chemical resistance. Unlike traditional materials, which may degrade under extreme temperatures or aggressive environments, flexible graphite maintains its integrity, making it a reliable choice for high-performance applications. Its ability to conform to uneven surfaces also enhances sealing capabilities, further optimizing efficiency and longevity.

In contrast, traditional gasket materials often suffer from limitations related to their operational envelope. Rubber gaskets, for instance, may become brittle over time, especially when exposed to harsh chemicals, while cork can compress and lose its sealing properties under sustained pressure. Flexible graphite, on the other hand, remains flexible and resilient, adapting to varying conditions without compromising seal integrity. This comparative analysis highlights why industries dealing with extreme conditions increasingly favor flexible graphite sheets over conventional materials, fostering improved operational reliability and cost-effectiveness.

Applications of Flexible Graphite Sheets in Various Industries

Flexible graphite sheets are increasingly recognized for their versatility and effectiveness in sealing applications across various industries. In the automotive sector, these sheets are utilized in gaskets for engines and exhaust systems, where high temperatures and resistance to chemical degradation are critical. According to a recent market analysis, the demand for flexible graphite materials in automotive applications is projected to grow at a CAGR of 5.3% through 2028, driven by advancements in electric and hybrid vehicle technologies.

In the industrial sector, flexible graphite sheets play a vital role in power generation and oil and gas applications. Their thermal stability and resistance to aggressive chemicals make them ideal for sealing in pipelines and reactors. The global flexible graphite market is anticipated to reach USD 1.3 billion by 2026, reflecting the material's essential role in improving operational efficiency and reducing downtime in these industries.

Tips: When selecting flexible graphite sheets for your applications, consider factors such as temperature range, chemical compatibility, and required thickness. It’s also beneficial to consult with industry experts to ensure you’re choosing the right material for your specific needs, maximizing both performance and cost-effectiveness.

Cost-Effectiveness and Performance Benefits of Graphite Sealing Solutions

When it comes to selecting sealing materials, the cost-effectiveness and performance benefits of flexible graphite sheets make them a top choice. These sheets boast an impressive resistance to high temperatures and harsh chemicals, ensuring that they can withstand extreme operating conditions while maintaining integrity and durability. This remarkable resilience means that users can anticipate fewer replacements and lower maintenance costs over time, ultimately translating into enhanced value for any project.

Additionally, the installation of graphite sealing solutions is typically straightforward, allowing for quicker assembly and reduced labor costs. Unlike conventional materials that may require intricate setups or numerous components, flexible graphite sheets can be cut to size and shaped to fit various applications easily. This adaptability not only facilitates efficient production processes but also helps in minimizing waste, contributing further to their cost-effectiveness. As industries continually seek reliable sealing options that do not compromise performance, flexible graphite emerges as an optimal solution that delivers both economic advantages and superior reliability.

Cost-Effectiveness and Performance Benefits of Graphite Sealing Solutions

Related Posts

-

Exploring the Varieties of Graphite Paper Spotlight: Understanding Its Types and Applications

-

Ultimate Guide to Sourcing Thermal Graphite Sheets for Enhanced Thermal Management Solutions

-

7 Essential Tips for Choosing the Perfect Graphite Gasket Sheet for Your Needs

-

What is Carbon Graphite Foil and Its Unique Applications in Industry

-

5 Innovative Ways the Best Graphite Cooling Film Can Transform Your Technology

-

Understanding the Advantages of Flexible Graphite Sheet in High Temperature Applications