10 Essential Tips for Choosing the Right Graphite Cooling Film for Your Needs

In the rapidly evolving world of electronic devices, the importance of thermal management is becoming increasingly paramount. One innovative solution that has garnered significant attention is the "Graphite Cooling Film." According to a recent report by Market Research Future, the global graphite cooling film market is projected to grow at a CAGR of 15.4% from 2023 to 2030, reflecting the rising demand for advanced cooling solutions in high-performance electronics. As devices become faster and more compact, choosing the right thermal management material is crucial to ensure optimal performance and longevity.

Dr. Emily Chen, a leading expert in materials science, states, “The right Graphite Cooling Film not only enhances heat dissipation but also contributes to the overall efficiency and reliability of electronic devices.” This encapsulates the essence of why making an informed choice in selecting graphite cooling films is vital for engineers and manufacturers alike. With various options available in terms of thermal conductivity, thickness, and adhesive properties, understanding your specific requirements is key to making the best selection. This guide aims to provide you with essential tips to navigate the complexities of choosing the right graphite cooling film for your needs, ultimately helping you achieve superior thermal management in your applications.

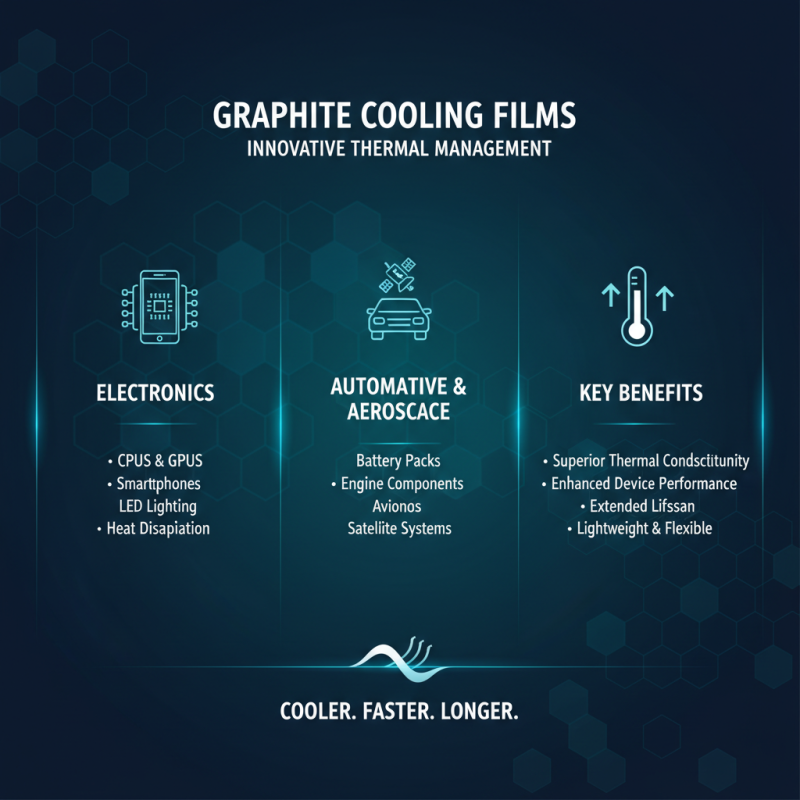

Understanding Graphite Cooling Films and Their Applications

Graphite cooling films are innovative materials designed to enhance thermal management across various applications. These films exhibit excellent thermal conductivity due to their unique structure and composition, making them ideal for electronic devices, automotive components, and aerospace technology. By dissipating heat efficiently, graphite cooling films help maintain optimal operating temperatures, thereby improving device performance and longevity.

Understanding the specific requirements for your application is crucial when selecting the right graphite cooling film. Factors such as thickness, thermal conductivity rating, and adhesive properties can significantly influence the film's effectiveness in a given scenario. For instance, in high-performance computing systems, thin films with exceptional thermal conductivity can be vital to prevent overheating. Conversely, in automotive applications, more robust films may be necessary to endure varying temperatures and mechanical stress. By considering these factors, you can make an informed choice that meets your cooling needs effectively.

Key Factors to Consider When Selecting Graphite Cooling Films

When selecting the right graphite cooling film for your specific application, there are several key factors to consider that can significantly impact performance and efficiency. One crucial aspect is the thermal conductivity of the film, which is often measured in watts per meter-kelvin (W/m·K). According to industry reports, high-quality graphite films can achieve thermal conductivities exceeding 1000 W/m·K, making them incredibly effective for heat dissipation in electronic devices, automotive components, and thermal management systems. Ensuring that the chosen film meets or exceeds these performance benchmarks will play a vital role in optimizing thermal efficiency and longevity.

Another important factor to evaluate is the thickness and flexibility of the graphite cooling film. Thinner films typically offer better adaptability to various surfaces and can be easier to integrate into compact designs. Additionally, the flexibility of the film influences its applicability in irregular or curved surfaces, which are common in modern electronic devices. Reports indicate that films as thin as 50 micrometers can still maintain excellent thermal performance, opening up new design possibilities while ensuring optimal heat management. It is essential to match the mechanical properties of the film with the operational demands of your application to achieve the best results.

Evaluating Thermal Conductivity and Performance Specifications

When selecting a graphite cooling film for your applications, evaluating thermal conductivity and performance specifications is imperative. Graphite films offer exceptional thermal management capabilities due to their high thermal conductivity, which can range from 300 to over 1500 W/m·K, depending on the material quality and processing techniques. According to industry reports, the thermal conductivity of a film significantly affects its ability to dissipate heat in electronic devices. For instance, studies demonstrate that a film with 1000 W/m·K thermal conductivity can effectively enhance heat dissipation in high-performance electronics, ensuring prolonged device longevity and reliability.

Moreover, it is essential to consider the operating conditions and expected performance metrics of the graphite film. Factors such as temperature range, mechanical properties, and thickness play crucial roles in determining whether a specific film meets your requirements. Recent technical assessments indicate that thinner films, while maintaining high thermal conductivity, can better conform to the surfaces of components, leading to improved thermal interface performance. Furthermore, films designed to withstand high temperatures without degrading ensure that they remain effective in demanding environments, with reports showing that certain formulations maintain their conductivity even at temperatures exceeding 250°C. Therefore, a thorough evaluation of these specifications is essential for achieving optimal thermal management in your applications.

10 Essential Tips for Choosing the Right Graphite Cooling Film for Your Needs - Evaluating Thermal Conductivity and Performance Specifications

| Film Type | Thermal Conductivity (W/m·K) | Thickness (mm) | Maximum Operating Temperature (°C) | Applications |

|---|---|---|---|---|

| High Conductivity Graphite Film | 1500 | 0.5 | 300 | LEDs, High-Power Electronics |

| Standard Graphite Cooling Film | 800 | 0.3 | 250 | Consumer Electronics, Power Supply Units |

| Ultra-Thin Graphite Film | 950 | 0.1 | 280 | Smartphones, Tablets |

| Flexible Graphite Film | 900 | 0.4 | 250 | Wearable Devices, Flexible Electronics |

| High Temperature Graphite Film | 1000 | 0.6 | 350 | Industrial Equipment, Automotive |

Assessing Compatibility with Your Specific Equipment or Setup

When selecting the right graphite cooling film, assessing compatibility with your specific equipment or setup is crucial. Different devices and environments may require distinct properties, such as thickness, thermal conductivity, and adhesion characteristics. Begin by evaluating the operational temperatures and pressure conditions of your equipment, as this will guide you toward selecting a film that can withstand such specifications without compromising performance.

One essential tip is to consult the technical data sheet of the graphite cooling film to ensure it aligns with your equipment’s requirements. Look for information on substrate compatibility, as materials may react differently when in contact with various surfaces. Additionally, consider the method of application. Some films are designed for easy peel-and-stick applications, while others may require specialized installation techniques that could influence compatibility with your setup.

Another important factor is the film's thermal performance. Prioritize films with high thermal conductivity ratings to ensure efficient heat dissipation, which is particularly essential for high-performance equipment. Testing samples before full-scale implementation can also be beneficial, allowing you to ascertain how well the film interacts with your system under real operating conditions. This proactive approach will help prevent any pitfalls associated with improper material selection and ensure optimal performance for your cooling needs.

10 Essential Tips for Choosing the Right Graphite Cooling Film for Your Needs

This chart illustrates the compatibility of different graphite cooling films based on thickness and thermal conductivity. It helps users assess which options may be optimal for their specific equipment or setup.

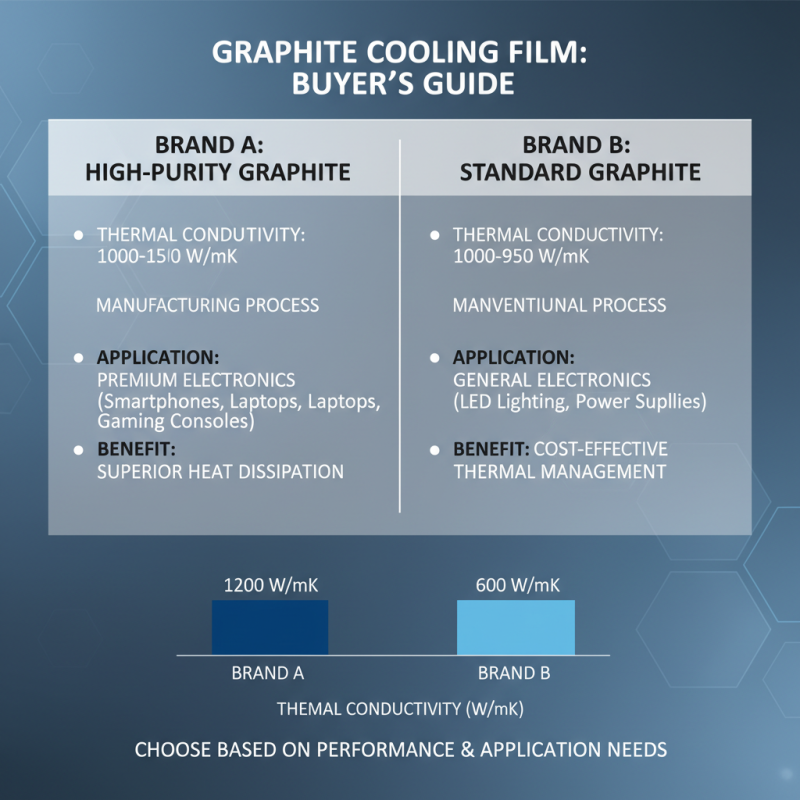

Comparative Analysis of Different Graphite Cooling Film Brands and Types

When selecting the right graphite cooling film, it's essential to conduct a thorough comparative analysis of the various brands and types available on the market. Recent industry reports indicate that the thermal conductivity of graphite cooling films can range from 300 to 1500 W/mK, with performance deeply influenced by the manufacturing process and material purity. For instance, high-purity graphite offers improved heat dissipation properties, making it ideal for applications in electronics where efficient thermal management is critical.

Furthermore, the thickness and flexibility of the film are important factors to consider. Studies indicate that films with a thickness of around 50 micrometers can provide optimal performance without compromising flexibility. This is particularly vital in applications involving curved surfaces or compact designs, where adaptability is necessary. Additionally, qualitative assessments often reveal that different brands may vary significantly in terms of durability and ease of application, which can directly impact the long-term performance of the cooling solution. By carefully comparing these characteristics across different products, users can make a more informed decision tailored to their specific cooling needs.

Related Posts

-

China's Leading Edge: The Evolution of the Best Graphite Thermal Sheets in Global Manufacturing

-

Understanding Industry Standards and Reasons Behind the Best Graphite Thermal Sheet Selection

-

Top 10 Thermal Graphite Sheet Manufacturers from China at the 137th Canton Fair

-

Exploring the Future: Advances in Graphite Thermal Film Technology by 2025

-

Unlocking Performance Enhancements with Best Graphite Thermal Film Benefits

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications