How to Choose the Right Graphite Thermal Sheet for Your Application

In today's high-tech landscape, the demand for effective thermal management solutions has significantly increased, especially in industries such as electronics, automotive, and renewable energy. According to a recent market report by MarketsandMarkets, the global thermal management market is projected to reach $24.6 billion by 2026, driven by the rising need for efficient heat dissipation in compact devices. A key component of these thermal solutions is the Graphite Thermal Sheet, known for its excellent thermal conductivity and mechanical properties. With thermal conductivity values often exceeding 1500 W/mK, these sheets are essential for applications requiring rapid heat transfer and management. As companies navigate through the complexities of product design and thermal efficiency, understanding how to choose the right Graphite Thermal Sheet tailored to specific application needs is paramount for achieving optimal performance and reliability.

Factors to Consider When Selecting Graphite Thermal Sheets for Electronics

When selecting graphite thermal sheets for electronic applications, several critical factors must be considered to ensure optimal performance. One significant aspect is the thermal conductivity of the material, which directly influences the efficiency of heat transfer between components. Industry reports indicate that high-performance thermal interface materials (TIMs) are essential for applications like space payloads, where managing heat is crucial for reliability and functionality. Choosing a graphite sheet with a thermal conductivity rating of at least 15 W/mK is advised to achieve effective thermal management.

Another key consideration is the physical dimensions and mechanical properties of the graphite thermal sheets. As highlighted in recent industry analyses, such as the IDTechEx report, the market for TIMs is expanding, and the choice of materials is becoming more diverse. The lateral size and loading ratio of materials like expanded graphite can significantly impact their mechanical and thermal properties, making it essential to choose the correct configuration for your specific application. For instance, optimal thermal conductivity can be obtained through tailored compositions that ensure efficient heat dissipation in electronic appliances, particularly in high-performance areas such as electric vehicle battery systems, which are increasingly reliant on advanced materials for thermal management.

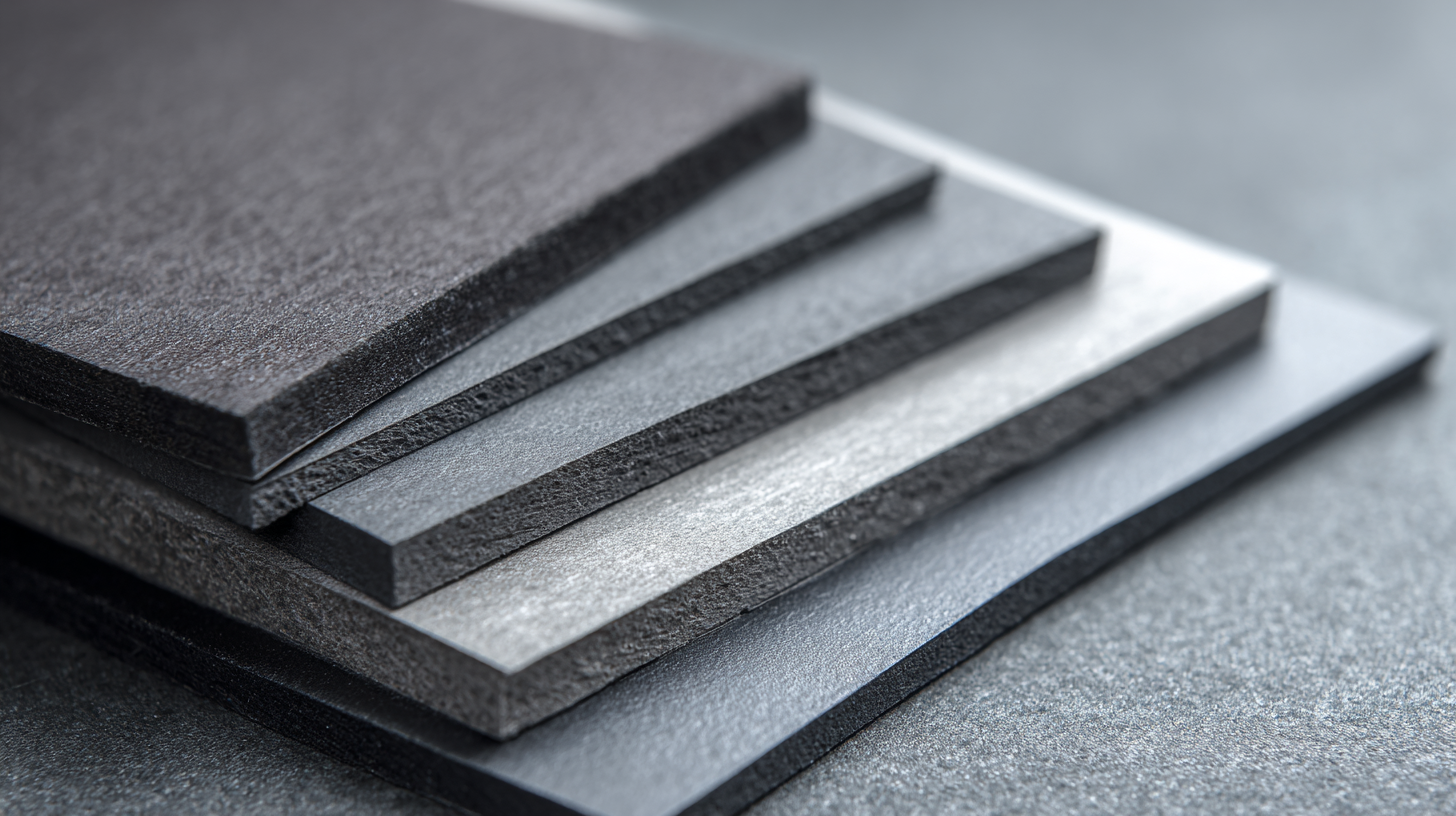

Understanding the Different Types of Graphite Thermal Sheets and Their Applications

When selecting the appropriate graphite thermal sheet for specific applications, it’s essential to understand the various types available and their unique properties. Graphite thermal sheets come in different forms, including flexible graphite sheets, expanded graphite, and compressed graphite. Each type exhibits distinctive thermal conductivity, thickness, and compressibility, making them suited for diverse uses in electronics, automotive, and industrial equipment. According to market projections, the flexible graphite market is expected to grow from USD 0.35 billion in 2025 to USD 0.45 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.5%. This growth indicates a rising demand for efficient thermal management solutions across various sectors.

Expanded graphite, in particular, possesses notable structural and elemental characteristics that enhance its usability in environmental applications. Its porous structure combined with oleophilic properties enables it to effectively sorb oils and heavy metals, making it a valuable component in environmental remediation strategies. This unique combination of properties highlights the importance of selecting the right type of graphite thermal sheet not only for enhancing thermal performance but also for addressing environmental concerns.

Understanding these differences can lead to more informed choices, optimizing both operational efficiency and sustainability in various applications.

Key Performance Metrics: Thermal Conductivity Ratings of Graphite Sheets

When selecting a graphite thermal sheet for your application, one of the most critical factors to consider is its thermal conductivity rating. Thermal conductivity is a measure of a material's ability to conduct heat, and it is essential for effective thermal management in electronic devices and industrial applications. Graphite sheets are well-known for their superior thermal conductivity, often measured in Watts per meter-Kelvin (W/mK). Understanding the specific requirements of your application will help you determine the appropriate thermal conductivity needed to ensure optimal performance.

In addition to raw thermal conductivity, it's important to look at the sheet's thickness and density. These characteristics can significantly influence the thermal performance. Thicker sheets typically provide better thermal resistance, but a balance must be struck to ensure they do not add excessive weight or bulk to the final product. Moreover, density can affect both mechanical stability and thermal transfer efficiency. By evaluating these performance metrics alongside the thermal conductivity ratings, you can better align the properties of the graphite thermal sheet with the demands of your specific application, ensuring effective heat dissipation and improved reliability.

How to Choose the Right Graphite Thermal Sheet for Your Application - Key Performance Metrics: Thermal Conductivity Ratings of Graphite Sheets

| Material Type | Thickness (mm) | Thermal Conductivity (W/mK) | Operating Temperature Range (°C) | Applications |

|---|---|---|---|---|

| High Purity Graphite | 0.5 | 150 | -40 to 200 | Consumer Electronics |

| Flexible Graphite | 0.3 | 120 | -30 to 250 | LED Lighting |

| Natural Graphite | 1.0 | 100 | -50 to 300 | Aerospace |

| Synthetic Graphite | 0.7 | 200 | -40 to 350 | Automotive |

| Graphite Film | 0.05 | 300 | -40 to 400 | High-Performance Computing |

Industry Standards and Certifications for Graphite Thermal Management Solutions

When selecting a graphite thermal sheet for your application, understanding industry standards and certifications is crucial. These regulations ensure that the materials used in thermal management meet specific performance criteria, providing reliability and safety in various environments. For instance, the ASHRAE 90.1 standard outlines energy efficiency requirements that thermal management solutions should adhere to, making it essential for manufacturers to align their products with these benchmarks.

Certifications such as UL (Underwriter Laboratories) and RoHS (Restriction of Hazardous Substances) further validate the quality and safety of graphite thermal sheets. A 2022 report from Transparency Market Research highlights that thermal management solutions that comply with UL certification not only enhance safety but can also improve the overall efficiency of electronic devices by up to 30%. This is particularly important in sectors such as electronics and automotive, where thermal management plays a vital role in product performance and durability.

Moreover, the growing demand for eco-friendly solutions has led to an increase in certifications like ISO 14001, which signifies a company’s commitment to environmental management. As stated in a 2023 report by Grand View Research, companies producing graphite thermal sheets that meet these eco-centric standards are more likely to attract environmentally-conscious consumers, ultimately influencing market growth. Therefore, selecting a graphite thermal sheet that complies with recognized industry standards and holds relevant certifications can significantly impact the success of your product.

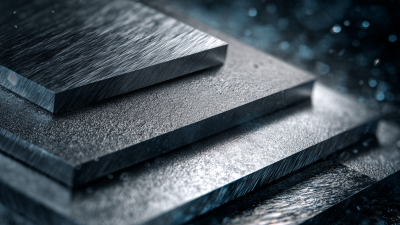

Comparative Analysis: Natural vs. Synthetic Graphite Thermal Sheets in Performance

When selecting the right graphite thermal sheet, understanding the differences between natural and synthetic graphite is crucial for optimal performance in your application. Natural graphite sheets are derived from naturally occurring graphite minerals and are typically characterized by their excellent thermal conductivity and mechanical flexibility. However, they often come with variability in quality and performance based on the source material. In comparison, synthetic graphite sheets offer a more consistent thermal performance and purity, making them ideal for applications requiring tight tolerances and reliability.

Tip 1: When evaluating the type of graphite thermal sheet, consider the specific thermal conductivity requirements of your application. If your project demands high thermal management, synthetic sheets may provide a more predictable solution.

On the other hand, the cost-effectiveness of natural graphite can be appealing for less demanding applications. Natural sheets can maintain strong thermal conductivity at a lower price point, but it’s essential to assess whether the variability could impact your overall performance.

Tip 2: Always conduct thorough testing in real-world conditions to ensure the chosen graphite thermal sheet meets your needs—this includes evaluating both initial thermal performance and long-term reliability.

Related Posts

-

Exploring the Future: Advances in Graphite Thermal Film Technology by 2025

-

China's Leading Edge: The Evolution of the Best Graphite Thermal Sheets in Global Manufacturing

-

Understanding Industry Standards and Reasons Behind the Best Graphite Thermal Sheet Selection

-

Top 10 Thermal Graphite Sheet Manufacturers from China at the 137th Canton Fair

-

Maximizing Value with Best Thermal Graphite Sheets: Service Benefits and Future Repair Innovations

-

Innovative Applications of Flexible Graphite Sheet in High Performance Industries