How to Choose the Right Flexible Graphite Packing for Your Applications

In the realm of industrial sealing solutions, the selection of the appropriate Flexible Graphite Packing can significantly influence operational efficiency and longevity. According to a report by MarketsandMarkets, the global market for graphite products is projected to reach $3.4 billion by 2026, driven by a rising demand for high-performance sealing materials across various sectors, including oil and gas, chemical processing, and power generation.

Flexible Graphite Packing stands out due to its exceptional thermal stability, resistance to chemical attack, and mechanical flexibility, making it ideal for high-temperature and high-pressure applications. However, choosing the right type and configuration requires a thorough understanding of specific application requirements and material properties. This guide aims to provide valuable insights into the critical factors to consider when selecting Flexible Graphite Packing, ensuring optimal performance and reliability in demanding environments.

Flexible Graphite Packing stands out due to its exceptional thermal stability, resistance to chemical attack, and mechanical flexibility, making it ideal for high-temperature and high-pressure applications. However, choosing the right type and configuration requires a thorough understanding of specific application requirements and material properties. This guide aims to provide valuable insights into the critical factors to consider when selecting Flexible Graphite Packing, ensuring optimal performance and reliability in demanding environments.

Factors to Consider When Selecting Flexible Graphite Packing

When selecting flexible graphite packing for specific applications, several critical factors must be considered to ensure optimal performance and reliability. First, the operating temperature range is paramount. Flexible graphite is renowned for its impressive temperature resistance, making it suitable for extreme conditions faced in industries such as oil & gas and chemical processing. With the flexible graphite market projected to reach approximately $450 million by 2030, focusing on high-performance sealing solutions becomes increasingly vital.

Another significant factor is the thermal conductivity required for your application. Flexible graphite's rapid heat dissipation capabilities are essential for applications like battery temperature management, particularly in the burgeoning electric vehicle market. As demand for advanced thermal management solutions rises, materials such as polyethylene glycol modified polysiloxane combined with silver-decorated expanded graphite composites exhibit exceptional thermal conductivity, with values cited as high as 23.4 W·m−1·K−1. Choosing the right flexible graphite packing not only enhances performance but also addresses various operational challenges, ensuring the longevity and efficiency of the equipment and systems in which they are used.

Understanding Different Types of Flexible Graphite Packing

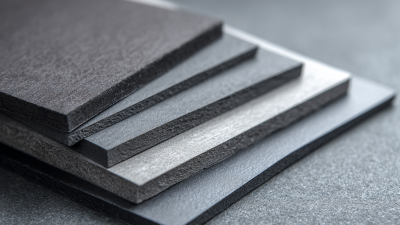

When choosing the right flexible graphite packing for your applications, it's essential to understand the different types available in the marketplace. Flexible graphite is known for its excellent thermal conductivity, making it suitable for applications involving heat dissipation. The market is projected to grow, with an estimated worth of $0.45 billion by 2030, driven by diverse applications such as gaskets and seals, thermal management, and EMI shielding. Each type—sheets, foils, and tapes—offers unique advantages depending on the specific requirements of your application.

For instance, sheets may be ideal for creating custom gaskets that require precise shapes, while foils can be used in applications demanding higher flexibility and compressibility. Tapes are often utilized in electronic appliances as thermal interface materials, effectively transferring heat between components and enhancing passive heat dissipation. Understanding these nuances will help you select the most suitable flexible graphite packing, ensuring optimal performance in your specific application.

For instance, sheets may be ideal for creating custom gaskets that require precise shapes, while foils can be used in applications demanding higher flexibility and compressibility. Tapes are often utilized in electronic appliances as thermal interface materials, effectively transferring heat between components and enhancing passive heat dissipation. Understanding these nuances will help you select the most suitable flexible graphite packing, ensuring optimal performance in your specific application.

Evaluating Performance Requirements for Your Specific Applications

When selecting flexible graphite packing for specific applications, it is crucial to evaluate the performance requirements meticulously. Factors such as temperature, pressure, and the nature of the media being contained must be considered. For example, applications involving high temperatures may necessitate packing that can withstand extreme heat without degrading, while those dealing with aggressive chemicals may require enhanced corrosion resistance. Understanding these parameters will help in selecting the right grade and configuration of flexible graphite packing to ensure optimal sealing performance.

Additionally, it’s important to assess the operational environment where the packing will be installed. Conditions such as vibration, movement, and the presence of particles can affect the longevity and efficiency of the sealing material. For dynamic applications, using a packing that maintains its integrity under variable conditions is essential. Moreover, consulting industry-specific guidelines and standards can provide further insight into the best practices for choosing flexible graphite packing tailored to unique performance demands. By aligning the packing specifications with the application's operational needs, one can achieve effective sealing solutions that minimize downtime and maintenance costs.

Installation and Maintenance Tips for Flexible Graphite Packing

When it comes to ensuring optimal performance from your flexible graphite packing, proper installation and maintenance are crucial. Flexible graphite packing is known for its high temperature and pressure resistance, making it ideal for various industrial applications. According to a report by MarketsandMarkets, the global flexible graphite market is expected to reach $500 million by 2026, highlighting its growing significance in industries such as oil and gas, chemical processing, and power generation.

For effective installation, it's essential to ensure that the sealing surfaces are clean and free from debris. A common tip is to avoid over-compressing the packing, as this can lead to premature wear or damage. Instead, aim for uniform compression that allows for the material's natural flexibility. Additionally, consider the temperature and pressure ratings of the graphite material you choose, as mismatched specifications can compromise system integrity.

Regular maintenance of your flexible graphite packing is equally important to prolong its lifespan. Inspect the packing periodically for signs of wear or leakage. If you notice any irregularities, replace the packing promptly to avoid more extensive damage. Using a lubrication system can also help reduce friction and wear, further enhancing the longevity of the installation. These proactive measures will contribute to a reliable sealing solution, ensuring that your operations continue smoothly.

How to Choose the Right Flexible Graphite Packing for Your Applications - Installation and Maintenance Tips for Flexible Graphite Packing

| Packing Type | Temperature Range (°C) | Pressure Rating (Bar) | Application Area | Installation Tips | Maintenance Tips |

|---|---|---|---|---|---|

| Style A | -240 to 700 | 30 | Chemical Process | Ensure proper compression during installation. | Inspect regularly for wear and tear. |

| Style B | -200 to 800 | 25 | Power Generation | Use appropriate sealing tools for installation. | Check for leakage and adjust tension as needed. |

| Style C | -250 to 600 | 20 | Oil & Gas | Align packing correctly to fit within the groove. | Regularly inspect for deterioration and replace when necessary. |

Common Mistakes to Avoid in Choosing Graphite Packing

When selecting flexible graphite packing for your applications, avoiding common pitfalls can significantly improve performance and durability. One of the most frequent mistakes is underestimating the importance of temperature and pressure ratings. It’s essential to ensure that the packing material can withstand the specific conditions of your operation. Many users opt for a universal packing solution, but the environmental parameters can vary widely, leading to premature failure or leakage.

Additionally, overlooking the compatibility with the fluid or gas being sealed can result in degradation of the packing material. Different substances can react poorly with certain graphite types, causing wear or breakdown. Always verify compatibility details before making your choice, as this can save you from costly downtime and replacements.

Tips: When in doubt, consult with manufacturer specifications or seek expert advice tailored to your specific needs. Another helpful tip is to consider the packing's installation method; improper installation can negate any advantages gained from selecting high-quality materials. Prioritizing these factors will lead to more reliable sealing solutions and ultimately enhance the efficiency of your operations.

Related Posts

-

Maximizing Value with Best Flexible Graphite Gaskets: After-Sales Support and Maintenance Cost Insights for a Sustainable Future

-

How to Choose the Right Graphite Thermal Sheet for Your Application

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications

-

Innovative Solutions for Graphite Paper Spotlight in Precision Manufacturing

-

Exploring Innovative Alternatives to Graphite Gasket Sheets for Diverse Applications

-

How to Enhance Your Battery Performance with Natural Flake Graphite