How to Choose the Best Flexible Graphite Gasket for High Temperature Applications

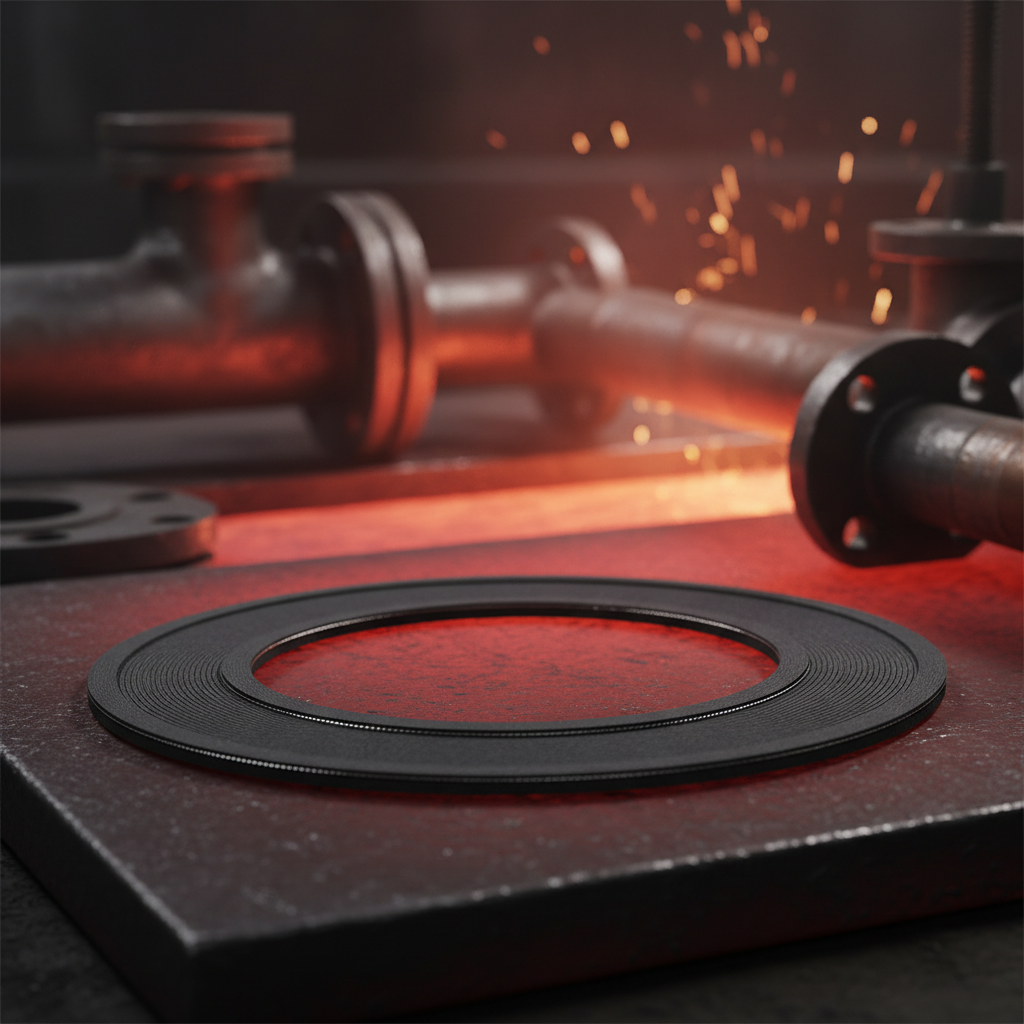

In high-temperature applications, the choice of gaskets plays a critical role in ensuring the integrity and reliability of machinery and systems. One of the most effective solutions for such demanding environments is the Flexible Graphite Gasket. Research indicates that the global gasket market is expected to reach USD 30 billion by 2025, with flexible graphite components increasingly favored for their excellent thermal stability and chemical resistance. Flexible graphite gaskets are designed to withstand temperatures exceeding 500°F and pressures up to 1000 psi, making them ideal for industries such as petrochemical, power generation, and marine.

The unique properties of Flexible Graphite Gaskets, which include high compressibility, low creep, and exceptional sealing capabilities, contribute to their growing acceptance among engineers and maintenance professionals. According to a report by the Global Market Insights, the demand for high-performance sealing solutions is projected to grow annually by 5% due to stringent leakage regulations and the need for reduced downtime in industrial operations. This underscores the importance of selecting the best Flexible Graphite Gasket for specific high-temperature applications, ensuring that critical systems operate efficiently and safely under extreme conditions.

Factors to Consider When Selecting Flexible Graphite Gaskets for High Temperature Use

When selecting flexible graphite gaskets for high temperature applications, several critical factors must be considered to ensure optimal performance and longevity. One primary consideration is the temperature tolerance of the gasket material. Flexible graphite is known for its excellent thermal conductivity and can withstand extreme temperatures, often exceeding 1000°C. This makes it suitable for industrial applications such as power generation and petrochemical processing, where high thermal resistance is crucial.

Another important aspect is the chemical compatibility of the gasket with the specific medium it will encounter. Flexible graphite gaskets provide excellent resistance to a wide range of chemicals, making them versatile for various applications. According to recent market analyses, the flexible graphite market is poised for growth, with projections indicating an increase from USD 0.35 billion in 2025 to USD 0.45 billion by 2030, signaling a compound annual growth rate (CAGR) of 5.5%. This growth underscores the rising demand for high-performance sealing solutions, which further emphasizes the importance of choosing the right gasket material tailored to specific high temperature and chemical conditions.

Understanding the Thermal Properties of Flexible Graphite Materials

When selecting the best flexible graphite gasket for high-temperature applications, understanding the thermal properties of flexible graphite materials is crucial. Flexible graphite exhibits remarkable thermal stability, making it an ideal choice for managing heat in various industrial environments. The thermal conductivity of flexible graphite significantly enhances its performance as a sealing material in high-temperature settings, allowing for efficient heat dissipation.

As the flexible graphite market continues to grow—projected to reach USD 0.45 billion by 2030, at a CAGR of 5.5% from 2025—there is increasing demand for advanced materials that can withstand extreme conditions. Products like innovative composites that integrate expanded graphite demonstrate improved thermal and mechanical properties, ensuring durability and reliability in high-stress applications. For instance, lauric acid-palmitic acid/expanded graphite composites have been developed as effective phase change materials for thermal energy storage, highlighting the versatile applications of flexible graphite in modern engineering solutions.

Key Features of High-Quality Flexible Graphite Gaskets

When selecting the best flexible graphite gasket for high-temperature applications, it is crucial to focus on specific key features that ensure performance and durability. High-quality flexible graphite gaskets should possess excellent thermal stability, capable of withstanding extreme temperatures without losing their structural integrity. Additionally, they must exhibit outstanding resistance to chemical corrosion, as they often operate in harsh environments involving aggressive fluids. The ability to provide an effective seal under dynamic and varying conditions is also vital, as leaks can lead to operational inefficiencies and safety hazards.

According to recent market analysis, the flexible graphite gasket market is projected to grow significantly, valued at $0.75 billion in 2022 and expected to reach $1.15 billion by 2030, with a compound annual growth rate of 5.5% between 2024 and 2030. This growth underscores the increasing demand for reliable sealing solutions in high-temperature applications across various industries. As technology advances and material science improves, manufacturers are continually developing gaskets that meet the evolving needs of high-performance environments, reinforcing the importance of choosing a gasket that not only meets current specifications but also anticipates future challenges.

Top Applications for Flexible Graphite Gaskets in Extreme Heat Conditions

Flexible graphite gaskets are increasingly vital in applications facing extreme heat conditions, where traditional sealing materials often fail. Industries that rely heavily on high-temperature environments, such as oil and gas, power generation, and chemical processing, benefit significantly from the unique properties of flexible graphite.

Its impressive thermal stability and resistance to chemical attack make it an ideal choice for maintaining integrity under severe temperatures, reducing the risk of leaks and enhancing overall operational efficiency.

Furthermore, the versatility of flexible graphite gaskets allows them to be tailored for specific applications, ensuring optimal performance in various high-temperature scenarios. For instance, in the petrochemical industry, these gaskets can withstand fluctuating pressures and temperatures, which are common during the refining process. Additionally, their lightweight nature and ease of installation provide significant advantages over heavier, bulkier materials, leading to better maintenance practices and reduced downtime.

With the increasing focus on safety and efficiency, flexible graphite gaskets are likely to see expanded use across multiple sectors, underscoring their importance in extreme heat applications.

Comparative Analysis of Leading Brands in Flexible Graphite Gaskets for 2025

When selecting the best flexible graphite gasket for high-temperature applications, it's essential to consider various factors, including material composition, temperature resistance, and brand reliability. The flexible graphite market is anticipated to grow significantly, projected to reach USD 0.45 billion by 2030, reflecting a steady annual growth rate. Key players in the graphite gasket industry are continually innovating their product offerings, ensuring that they meet the rigorous demands of high-heat environments.

Tips: When choosing a gasket, always compare the thermal conductivity ratings of different brands, as this can significantly affect performance under extreme conditions. Additionally, consider the compatibility of the gasket material with the chemicals it will encounter in the application, as this impacts longevity and effectiveness.

Conducting thorough research on leading brands can greatly aid in making an informed choice. Look for user testimonials and third-party reviews to understand the performance and durability of their products. Keeping an eye on industry trends for 2025 will also provide valuable insights into emerging technologies and materials in the flexible graphite gasket market, enabling you to select the most effective solution for your needs.

Related Posts

-

Maximizing Value with Best Flexible Graphite Gaskets: After-Sales Support and Maintenance Cost Insights for a Sustainable Future

-

Exploring Future Innovations in Best Flexible Graphite Gasket Technology for 2025

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications

-

Exploring Innovative Alternatives to Graphite Gasket Sheets for Diverse Applications

-

5 Essential Tips for Choosing the Right Flexible Graphite Gasket for Your Applications

-

7 Essential Tips for Choosing the Perfect Graphite Gasket Sheet for Your Needs