What is Carbon Graphite Foil and Its Unique Applications in Industry

Carbon Graphite Foil, a versatile and innovative material, has garnered significant attention across various industries due to its unique properties and applications. According to a recent market report by ResearchAndMarkets, the global carbon materials market is projected to reach USD 37.4 billion by 2025, driven by the increasing demand for lightweight, high-strength materials in sectors such as automotive, aerospace, and electronics. The exceptional thermal conductivity, chemical resistance, and high-temperature stability of Carbon Graphite Foil make it an ideal solution for applications ranging from seals and gaskets to thermal management in electronic devices.

Additionally, its ability to operate efficiently under extreme conditions positions it as a critical component in advanced applications, including fuel cells and battery technologies. As industries continue to seek more efficient and sustainable material alternatives, Carbon Graphite Foil stands out as a formidable choice that aligns with the growing emphasis on performance and sustainability.

Additionally, its ability to operate efficiently under extreme conditions positions it as a critical component in advanced applications, including fuel cells and battery technologies. As industries continue to seek more efficient and sustainable material alternatives, Carbon Graphite Foil stands out as a formidable choice that aligns with the growing emphasis on performance and sustainability.

What is Carbon Graphite Foil and How is it Manufactured?

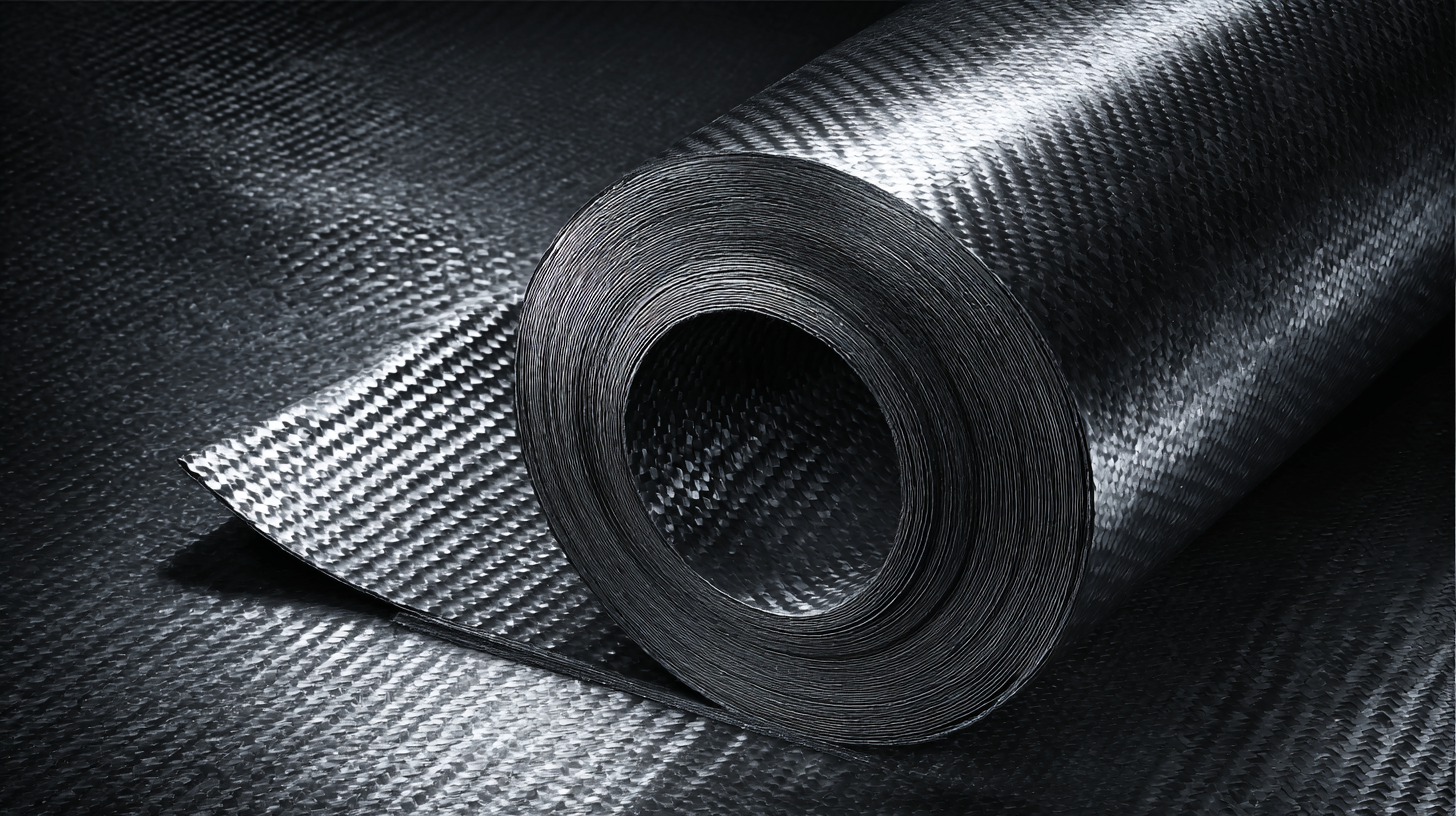

Carbon graphite foil is a versatile material derived from the processing of carbon-based raw materials, which can include recycled fibers and other carbon-rich sources. Its manufacturing process typically involves the thermal treatment of these precursor materials to produce a stable, flexible, and thin foil capable of withstanding high temperatures and harsh chemical environments. Recent advancements in the synthesis of graphene nanosheets from materials like coconut and candlenut shells further highlight the potential for more sustainable production methods that not only reduce waste but also enhance material properties.

The unique characteristics of carbon graphite foil make it particularly suitable for a wide range of industrial applications. Its excellent thermal and electrical conductivity, combined with its resistance to chemical degradation, positions it as an ideal option for applications in electronics, energy storage, and composite materials. Furthermore, initiatives to reclaim waste carbon fibers for the development of high-performance composites signify a paradigm shift towards sustainability in the manufacturing sector, aligning with the growing demand for environmentally friendly materials. As industries continue to explore innovative production techniques and materials, carbon graphite foil's role is expected to expand, reflecting its significance in future applications.

Key Properties of Carbon Graphite Foil that Enhance Industrial Performance

Carbon graphite foil is a versatile material known for its unique properties that significantly enhance industrial performance. With a flexible structure, it offers exceptional thermal conductivity, high-temperature stability, and excellent sealing capabilities. These characteristics make it ideal for applications in industries such as electronics, automotive, and energy, where efficient thermal management is paramount. According to market estimates, the flexible graphite market is projected to grow from $0.35 billion in 2025 to $0.45 billion by 2030, highlighting its increasing relevance in advanced manufacturing.

Tip: When selecting carbon graphite foil, consider its thermal conductivity rating and temperature tolerance to ensure optimal performance in your specific application.

Tip: When selecting carbon graphite foil, consider its thermal conductivity rating and temperature tolerance to ensure optimal performance in your specific application.

Moreover, the growing demand for lithium-ion batteries in the U.S. further fuels the need for graphite-based materials, underscoring their critical role in the energy transition. As industries seek to enhance efficiency and sustainability, carbon graphite foil stands out as a reliable choice for achieving these goals. Its mechanical, thermal, and electrical properties not only support innovative designs but also align with modern manufacturing trends.

Tip: Explore variations of graphite composites to maximize performance benefits while addressing specific environmental and operational challenges.

Unique Applications of Carbon Graphite Foil Across Various Industries

Carbon graphite foil is gaining significant traction in various industries due to its unique properties and versatile applications. The flexible graphite market, valued at approximately USD 0.35 billion in 2025, is expected to witness growth, reaching USD 0.45 billion by 2030, with a compound annual growth rate (CAGR) of 5.5%. This growth is driven by the increasing demand for efficient sealing materials, heat exchangers, and thermal management systems in sectors such as automotive, aerospace, and electronics.

In automotive applications, carbon graphite foil serves as an ideal material for gaskets and seals, owing to its excellent thermal conductivity and chemical resistance. Advanced composite materials that incorporate graphite contribute to the lightweight and sustainable manufacturing processes vital in modern automobiles. Furthermore, the innovative use of graphite in energy storage solutions, such as supercapacitors, showcases its adaptability. Recent studies demonstrate that the in-situ growth of copper nanoparticles over graphene composite sheets leads to enhanced electrode materials, illustrating the promising intersection of graphite technology and clean energy advancements.

What is Carbon Graphite Foil and Its Unique Applications in Industry

| Industry | Application | Benefits | Typical Thickness |

|---|---|---|---|

| Aerospace | Sealing components in engines | High temperature resistance, lightweight | 0.05 - 1.0 mm |

| Electronics | Thermal management solutions | Efficient heat conduction, energy savings | 0.1 - 0.5 mm |

| Automotive | Gaskets and seals | Chemical resistance, durability | 0.2 - 1.0 mm |

| Energy | Fuel cell membranes | High efficiency, lightweight | 0.05 - 0.2 mm |

| Manufacturing | Lubrication in high-performance machinery | Low friction, high wear resistance | 0.1 - 2.0 mm |

Advantages of Using Carbon Graphite Foil Over Traditional Materials

Carbon graphite foil is increasingly recognized in various industries for its unique properties and advantages over traditional materials. One major benefit is its exceptional thermal conductivity, which allows for efficient heat transfer in applications such as electronics, automotive, and aerospace. Unlike metal foils, carbon graphite foil can maintain its structural integrity at high temperatures, making it ideal for use in extreme conditions where other materials might fail.

Another significant advantage is its lightweight nature combined with strength. This foil offers a high strength-to-weight ratio, enabling manufacturers to create lighter products without compromising durability. Applications in the automotive sector, particularly for fuel efficiency, highlight this property. Additionally, carbon graphite foil exhibits excellent chemical resistance, making it suitable for use in harsh environments, such as in chemical processing or corrosion-prone areas. Overall, the unique properties of carbon graphite foil make it a superior choice for innovative manufacturing processes and applications that require reliable, high-performance materials.

Future Trends in Carbon Graphite Foil Technology and Applications

The future trends in carbon graphite foil technology indicate an exciting evolution driven by advancements in materials science and engineering. With the global push for more sustainable and efficient manufacturing processes, carbon graphite foil is gaining traction across various industries. Innovations in production methods are enhancing the foil's properties, such as conductivity, thermal resistance, and flexibility, making it an ideal candidate for applications in electronics, automotive, and renewable energy sectors. As companies seek lightweight and durable materials, carbon graphite foil is set to play a crucial role in the development of next-gen batteries and electric vehicles.

Moreover, the integration of nanotechnology into the production of carbon graphite foil is expected to reveal new functionalities and applications. This trend will likely lead to the creation of foils with superior mechanical strength and resistance to extreme temperatures. Such advancements could open doors for their use in aerospace and high-performance industrial machinery. As research continues to uncover the potential of carbon graphite foil, its adaptability and performance are anticipated to reshape manufacturing processes, ultimately enhancing product efficiency and sustainability.

Carbon Graphite Foil Applications and Market Trends

Related Posts

-

Exploring the Varieties of Graphite Paper Spotlight: Understanding Its Types and Applications

-

Innovative Applications of Flexible Graphite Sheet in High Performance Industries

-

Ultimate Guide to Sourcing Thermal Graphite Sheets for Enhanced Thermal Management Solutions

-

What is Flexible Graphite Sheet and How It Revolutionizes Industrial Applications?

-

Exploring the Versatility of the Best Graphite Sheet: Unique Use Cases and Applications

-

Exploring Innovative Alternatives to Graphite Gasket Sheets for Diverse Applications