Top 10 Benefits of Using Natural Graphite Sheet for Your Applications

In recent years, the demand for high-performance materials in various industrial applications has surged, leading to the exploration of innovative solutions that enhance efficiency and durability. Among these materials, the Natural Graphite Sheet stands out due to its exceptional thermal and electrical conductivity, making it an ideal choice for a wide range of applications. As industries seek to optimize their processes and improve product performance, understanding the benefits of incorporating Natural Graphite Sheet into their operations becomes crucial.

This article delves into the top ten advantages of utilizing Natural Graphite Sheet in various applications. From its ability to withstand extreme temperatures to its environmentally friendly nature, Natural Graphite Sheet offers a multitude of benefits that can significantly impact operational efficiency and product longevity. By highlighting these advantages, we aim to provide valuable insights for engineers and decision-makers looking to leverage the unique properties of Natural Graphite Sheet in their projects. As we explore these benefits, it becomes clear why this versatile material is gaining traction across numerous sectors and is poised to play a pivotal role in future innovations.

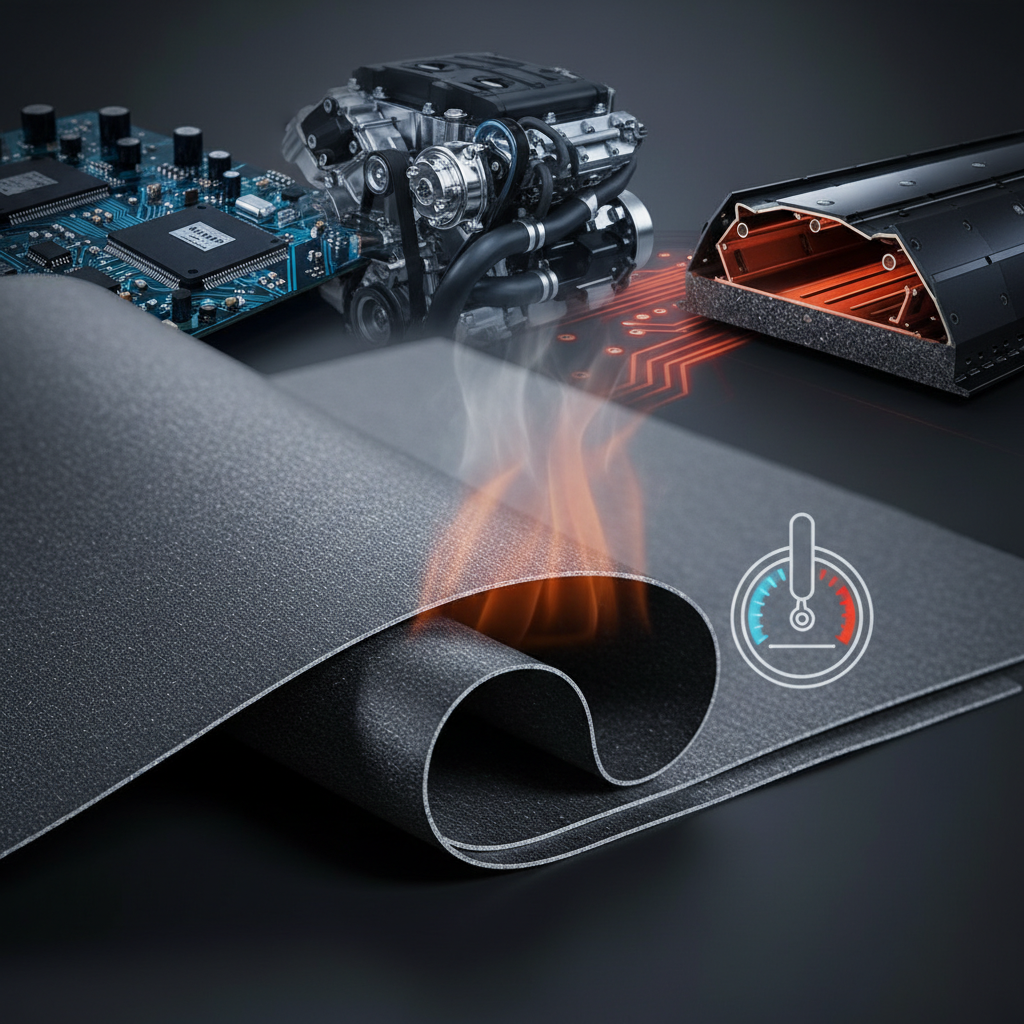

Advantages of High Thermal Conductivity in Natural Graphite Sheets

Natural graphite sheets offer significant advantages due to their high thermal conductivity, which makes them excellent for applications requiring effective heat management. The flexible graphite market, projected to grow from USD 0.35 billion in 2025 to USD 0.45 billion by 2030 at a CAGR of 5.5%, indicates a rising demand for materials that can efficiently transfer heat. This is particularly critical in industries like electronics and automotive, where overheating can lead to performance issues and reduce lifespan.

Utilizing natural graphite sheets can also enhance the performance of thermal energy storage systems. Studies have shown that carbon-based composite phase change materials benefit greatly from incorporating graphite, improving their thermal performance significantly. The integration of natural graphite results in better heat transfer capabilities, making them ideal for various thermal applications.

**Tips:** When selecting materials for thermal management, consider natural graphite sheets for their superior conductivity. Additionally, keep an eye on market trends; as demand for high-performance materials grows, so do innovations in graphite technology that can enhance your applications. Lastly, evaluate the long-term cost benefits of using natural graphite in reducing energy waste and improving system efficiency.

Top 10 Benefits of Using Natural Graphite Sheet for Your Applications

Enhanced Durability and Longevity of Graphite Sheet Applications

Natural graphite sheets are increasingly recognized for their exceptional durability and longevity, making them an ideal choice for various applications in industries such as electronics, automotive, and aerospace. One of the key benefits of natural graphite sheets is their resistance to wear and tear. Unlike synthetic alternatives, natural graphite maintains its structural integrity even under high temperature and pressure conditions. This resilience ensures that applications can function effectively over extended periods without frequent replacements, thereby reducing operational costs.

Additionally, the thermal stability of natural graphite sheets contributes significantly to their longevity. They can withstand extreme thermal fluctuations without degrading, which is crucial in applications that involve heat dissipation. Their ability to provide consistent performance over time means that businesses can rely on them for long-term projects. The combination of these attributes not only enhances the overall performance of the final products but also supports sustainability by minimizing waste and resource consumption associated with frequent maintenance or replacements.

Cost-Effectiveness of Natural Graphite Sheets in Manufacturing

Natural graphite sheets are increasingly recognized for their cost-effectiveness, particularly in manufacturing processes that demand high-quality materials. The versatility of graphite makes it a crucial component in various applications, such as in electrochemistry research and the growing lithium-ion battery market. By utilizing natural graphite, manufacturers can achieve significant cost savings while maintaining high performance and reliability. The intrinsic properties of graphite, including its exceptional lubricity and thermal conductivity, enable the production of more efficient products without the need for expensive alternatives.

The cost analysis of natural graphite reveals its competitive advantage over synthetic options, which often require higher investments in production. As industries seek to minimize expenses while enhancing product quality, natural graphite sheets present an appealing solution. As the market expands, particularly in sectors like flexible graphite and battery technology, the demand for cost-effective materials will only increase. This trend underscores the importance of natural graphite in developing sustainable, high-performance applications that do not compromise on cost.

Environmentally Friendly Properties of Natural Graphite Materials

Natural graphite materials are increasingly recognized for their environmentally friendly properties, making them a superior choice across various applications. One of the most compelling advantages is their origin; natural graphite is derived from the earth, which offers a sustainable advantage over synthetic alternatives. According to a report by the Global Graphite Market Analysis, natural graphite has a lower carbon footprint, emitting about 30% less CO2 compared to synthetic graphite during its production process. This significant reduction aligns with growing industry demands for greener materials, especially in sectors like electronics and batteries.

Moreover, the recyclability of natural graphite enhances its eco-friendly appeal. Research by the International Energy Agency highlights that components made from natural graphite can be reused and repurposed, reducing waste and the need for virgin materials. This aligns with circular economy principles that are essential for sustainable development. Additionally, natural graphite’s non-toxic nature poses fewer health risks to workers in manufacturing settings, highlighting its role as a safe alternative in the production of energy storage solutions. As businesses increasingly prioritize sustainability, the shift towards natural graphite materials is not just an environmental choice but also a strategic move towards long-term viability in various applications.

Versatility of Natural Graphite Sheets Across Various Industries

Natural graphite sheets have found widespread application across various industries due to their unique properties. In the electronics sector, for instance, the rise of electric vehicles (EVs) and renewable energy technologies has bolstered the demand for efficient thermal management solutions. A report from MarketsandMarkets suggests that the global market for thermal management materials, which includes natural graphite sheets, is projected to reach $22.3 billion by 2025, highlighting the growing importance of these materials in maintaining optimal operating temperatures for advanced electronics.

In the aerospace and automotive industries, the versatility of natural graphite sheets is evident in their use for gaskets and seals. According to a study by Research and Markets, the market for gaskets is expected to grow significantly, reaching $66.4 billion by 2022, driven by an increase in demand for high-performance sealing materials. The excellent thermal and chemical resistance of natural graphite makes it an ideal choice for applications that require high durability and reliability under extreme conditions. As industries continue to innovate and prioritize sustainability, the use of natural graphite sheets is likely to expand, making them a valuable asset in diverse applications.

Related Posts

-

What Makes Graphite Sheets the Ideal Choice for Industrial Applications

-

Exploring the Varieties of Graphite Paper Spotlight: Understanding Its Types and Applications

-

5 Essential Tips for Choosing Graphite Paper Officeworks for Your Business Needs

-

Top 5 Benefits of Using Flexible Graphite Gaskets for Industrial Applications

-

Unlocking Superior Performance with Best Flexible Graphite Sheets from Leading Chinese Manufacturers

-

China's Leading Edge: The Evolution of the Best Graphite Thermal Sheets in Global Manufacturing