Top 5 Benefits of Using Graphite Lining Paper for Your Projects

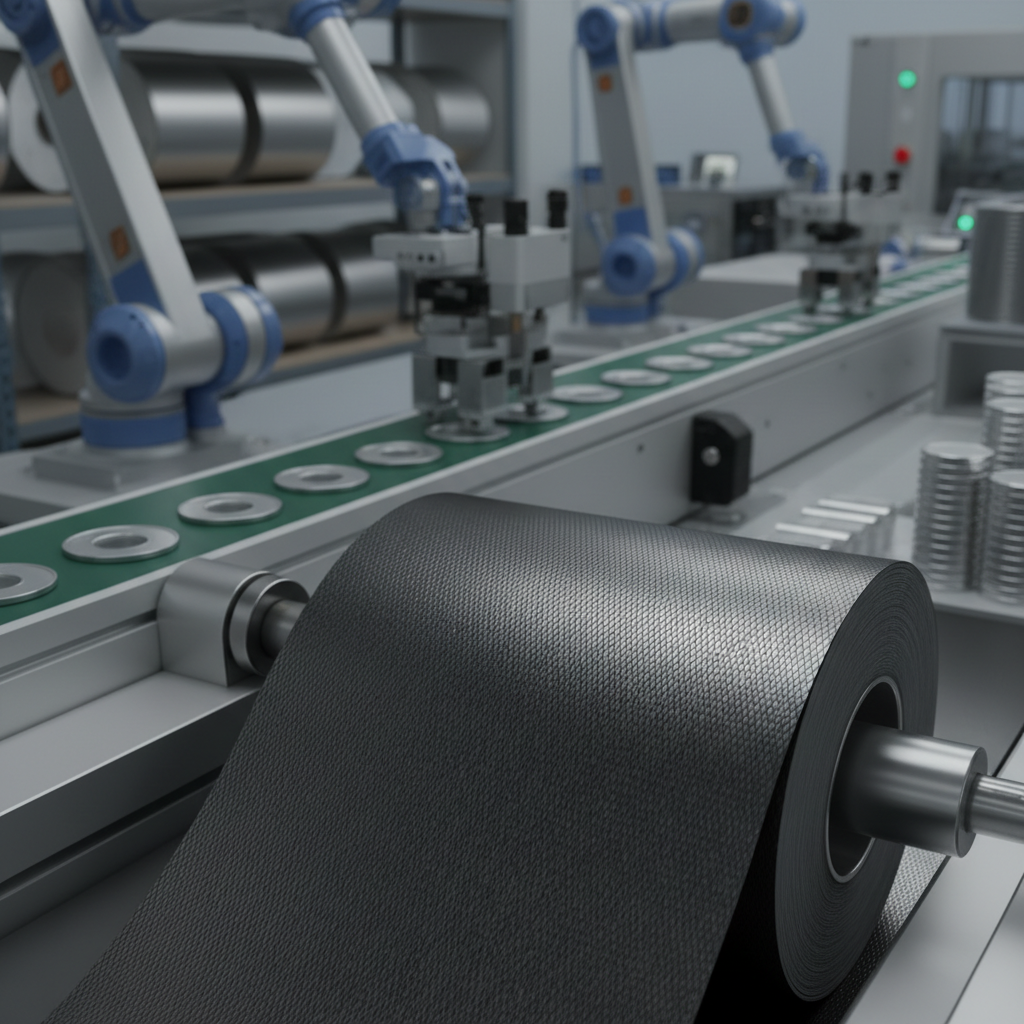

In the realm of modern manufacturing and construction, the use of innovative materials has become increasingly essential. One such material making waves due to its unique properties is Graphite Lining Paper. According to a recent report by the International Association of Materials Science (IAMS), the demand for advanced materials like Graphite Lining Paper is projected to grow by 15% annually, driven by its applications in industries such as aerospace, automotive, and electronics. This substantial growth not only highlights the material's versatility but also its performance advantages in enhancing product durability and efficiency.

Expert in materials engineering, Dr. Lisa Thomson, emphasizes the significance of Graphite Lining Paper in contemporary projects, stating, "The superior thermal and chemical resistance of Graphite Lining Paper allows for unparalleled performance, particularly in environments that demand resilience under extreme conditions." With its unique composition, Graphite Lining Paper serves as an exceptional solution for projects requiring reliable insulation and protection, setting a benchmark for quality and innovation in material selection. As we delve into the top five benefits of using Graphite Lining Paper, it’s crucial to recognize how this remarkable material can elevate your project outcomes and drive success.

Understanding the Unique Properties of Graphite Lining Paper

Graphite lining paper is a remarkable material recognized for its unique properties, making it an ideal choice for various projects, particularly in art and design. This specialized paper offers excellent durability and resistance to tearing, allowing for precise application and long-lasting results. The inherent lubricity of graphite improves the sliding capability between layers, enabling smoother and more controlled finish on surfaces.

When working with graphite lining paper, it's essential to know how to maximize its benefits. One tip is to use a sharp knife or blade when cutting the paper to prevent fraying and ensure clean edges. Additionally, be mindful of the weight and thickness of the paper; heavier grades can provide better stability for detailed projects but may require more pressure during application.

Another advantage of graphite lining paper is its thermoplastic nature, allowing it to conform to various shapes and surfaces. This flexibility is perfect for creating intricate designs or coverings on curved surfaces. A helpful tip is to warm the paper slightly before application; this will make it more malleable and easier to work with, providing an excellent fit on complex shapes. By understanding these unique properties and tips, you can harness the full potential of graphite lining paper in your projects.

Enhancing Durability and Longevity in Your Projects with Graphite

Graphite lining paper is an exceptional material that significantly enhances the durability and longevity of various projects. This advanced product utilizes the remarkable properties of graphite, which has a natural resistance to wear and tear. When applied as a lining in construction, arts, or crafting, it provides a protective barrier against moisture, dirt, and other environmental stresses. This means that projects can withstand the test of time, offering an enduring finish that reduces the need for repairs and maintenance.

Moreover, the flexibility and lightweight nature of graphite lining paper make it easy to work with. This enables designers and builders to incorporate it seamlessly into their projects without compromising other design elements. Additionally, the unique composition of graphite allows for excellent thermal stability, further protecting the underlying surfaces from extreme temperatures and thermal shocks. By choosing graphite lining paper, project creators can ensure that their work not only looks great but also stands strong against potential damage, paving the way for greater satisfaction and value over time.

Improving Cost-Efficiency Through Graphite Lining Paper Usage

The use of graphite lining paper in projects offers significant improvements to cost-efficiency, particularly when applied in industries like battery manufacturing. Graphite, known for its excellent conductive properties, serves as a reliable material for current collectors in lithium-ion batteries and supercapacitors. By utilizing graphite lining paper, manufacturers can minimize material costs while enhancing the overall performance of their products. This efficient resource allocation allows companies to remain competitive in a rapidly evolving market.

Moreover, graphite lining paper facilitates lighter and thinner designs, which is crucial for modern applications where weight and size constraints are prevalent. Lowering the weight of components directly contributes to energy efficiency, further driving down costs in transportation and material usage. Its adaptability across various substrates reinforces its utility, allowing manufacturers to streamline production processes and reduce waste. As a result, the integration of graphite lining paper not only promotes cost savings but also supports sustainable practices in project execution.

Boosting Aesthetic Appeal: Graphite Lining for Design Projects

Graphite lining paper serves as a versatile tool in design projects, significantly enhancing aesthetic appeal. Its unique texture and subtle sheen can elevate the visual dynamics of a space, adding depth and sophistication. Designers can use graphite lining paper to create striking contrasts against lighter materials, thereby highlighting specific elements in their work. This distinctive feature makes it an ideal choice for contemporary interiors and art installations, where bold statements are essential.

Moreover, the adaptability of graphite lining paper allows for seamless integration into various design styles, from minimalist to eclectic. It can be applied to walls, furniture, or even as a backdrop for artistic displays. This versatility not only adds an element of surprise but also enables designers to explore innovative patterns and textures that evoke emotion and interest. By incorporating graphite lining into their projects, designers can create environments that are not only visually appealing but also resonate with the intended aesthetic narrative.

Top 5 Benefits of Using Graphite Lining Paper for Your Projects

| Benefit | Description | Impact on Design Projects |

|---|---|---|

| Enhanced Aesthetic Appeal | Graphite lining paper adds a unique texture and matte finish that elevates visual design. | Engages viewers and creates a sophisticated atmosphere. |

| Durability | Offers long-lasting performance suitable for various applications. | Sustains the integrity of design over time. |

| Easy to Work With | Lightweight and easily cut, making customization simple. | Facilitates creative flexibility in project execution. |

| Variety of Applications | Suitable for art, décor, and product packaging. | Enhances multiple design contexts across industries. |

| Sustainable Option | Can be made from recycled materials, contributing to eco-friendliness. | Appeals to environmentally-conscious consumers and brands. |

Versatile Applications of Graphite Lining Paper Across Industries

Graphite lining paper is rapidly becoming a cornerstone in various industries due to its unique properties and versatile applications. Its high thermal resistance and excellent lubricity make it ideal for use in automotive and aerospace sectors, where precision and durability are paramount. According to a recent report by MarketsandMarkets, the global graphite paper market is projected to grow to $1.2 billion by 2025, reflecting its increasing adoption across multiple applications. In the automotive industry, for instance, graphite lining paper is essential in reducing friction in engine components, leading to improved fuel efficiency and extended lifespan of parts.

Another significant application of graphite lining paper is in the electronics industry, where it is utilized for thermal management in devices like computers and smartphones. The ability of graphite to dissipate heat efficiently helps in enhancing the performance and reliability of electronic devices. An analysis by Research and Markets indicates that the electronic component market for thermal management solutions is expected to reach $3 billion by 2024, highlighting the growing need for materials such as graphite lining paper. As industries continue to push the boundaries of technology, the versatility and performance of graphite lining paper position it as a vital resource for innovative project development across various sectors.

Related Posts

-

What is Flexible Graphite Sheet and How It Revolutionizes Industrial Applications?

-

Innovative Solutions for Graphite Paper Spotlight in Precision Manufacturing

-

Exploring Market Trends: Thermal Graphite Sheets at the 138th Canton Fair 2025 in China

-

Innovative Applications of Flexible Graphite Sheet in High Performance Industries

-

Unmatched Quality and Reliability in Best Graphite Natural Products from Trusted Chinese Manufacturers

-

How to Use Graphite Paper Staples for Effective Drawing and Design