Top 10 Benefits of Graphite Gasket Sheets You Should Know About

In the industrial landscape, the significance of Graphite Gasket Sheets cannot be overstated, particularly in applications requiring high performance and reliability under extreme conditions. According to a recent market analysis by Technavio, the global gasket market is projected to grow at a CAGR of 4.5% from 2023 to 2028, driven primarily by the enhanced durability and performance of materials like graphite. This growth underscores the increasing recognition of the advantages that Graphite Gasket Sheets provide across various sectors, especially in environments characterized by high temperature and pressure.

Dr. Emily Carter, a leading expert in gasket technology, emphasizes the importance of these materials when she states, "Graphite Gasket Sheets offer unparalleled resilience and versatility, making them essential for ensuring leak-proof sealing in critical applications." The unique properties of graphite, such as its thermal conductivity, chemical resistance, and ability to withstand significant stress, make Graphite Gasket Sheets an ideal choice for industries ranging from energy to manufacturing. As businesses strive for greater efficiency and safety, understanding the top benefits of Graphite Gasket Sheets becomes vital for engineers and decision-makers alike.

Benefits of Graphite Gasket Sheets in High-Temperature Applications

Graphite gasket sheets

are renowned for their exceptional performance in high-temperature applications, making them a vital component in various industries. One of the primary advantages of graphite is its ability to withstand extreme temperatures, often exceeding 1000°C in applications where traditional materials may fail. This thermal stability ensures that the gaskets maintain their integrity and sealing capabilities under intense conditions, preventing leaks and ensuring operational efficiency.

Moreover, graphite's inherent resistance to oxidation adds to its viability in high-temperature environments. Unlike many other materials that degrade or compromise under prolonged exposure to heat, graphite remains resilient, providing a reliable sealing solution. This characteristic is particularly beneficial in industries like petrochemical, power generation, and aerospace, where maintaining tight seals in high-pressure and high-temperature systems is crucial for safety and performance.

In summary, the application of graphite gasket sheets in high-temperature scenarios underscores their importance in enhancing reliability and longevity in demanding environments.

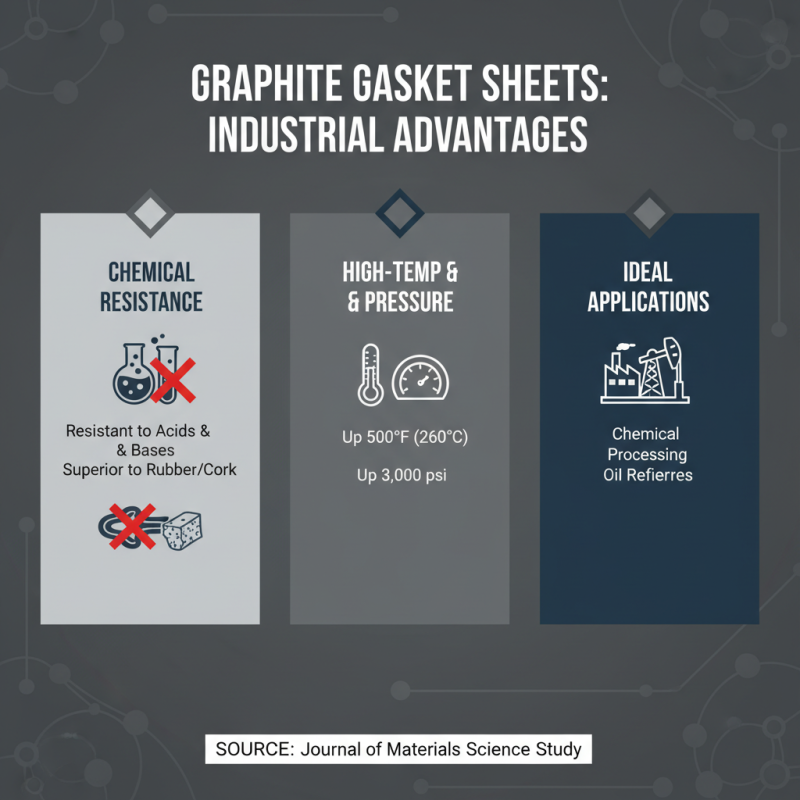

Enhanced Chemical Resistance of Graphite Gasket Sheets Compared to Alternatives

Graphite gasket sheets have gained significant attention in the industrial sector due to their exceptional resistance to harsh chemicals and high-temperature environments. Unlike traditional materials like rubber or cork, graphite gaskets demonstrate an impressive ability to withstand aggressive chemicals, including acids and bases. According to a study published by the Journal of Materials Science, graphite gaskets can endure temperatures up to 500°F (260°C) and pressures of 3,000 psi in corrosive environments, making them an ideal choice for applications in chemical processing plants and oil refineries.

Moreover, the enhanced chemical resistance of graphite gasket sheets is attributed to their molecular structure, which allows for a unique combination of flexibility and strength. A report from the American Society of Mechanical Engineers highlights that these gaskets exhibit minimal degradation when exposed to various chemicals, unlike conventional gaskets that may swell, shrink, or lose integrity over time. This resilience not only ensures a reliable seal but also leads to reduced maintenance costs and downtime. As industries increasingly seek durable and high-performance materials, the adoption of graphite gasket sheets continues to rise, demonstrating their critical role in maintaining operational efficiency and safety in demanding environments.

Cost Efficiency: Long-Term Savings with Graphite Gasket Sheets

Graphite gasket sheets are increasingly recognized for their cost efficiency, offering significant long-term savings for various industrial applications. A recent industry report highlighted that the lifetime of graphite gaskets is typically twice that of conventional materials, significantly reducing replacement costs. Furthermore, their superior resistance to heat and chemical exposure means they maintain integrity longer under extreme conditions, reducing maintenance downtime and costs. According to the latest data, businesses can expect a savings increase of up to 30% when utilizing graphite gasket sheets over traditional alternatives.

To maximize these savings, it's essential to assess the specific applications and conditions where the gaskets will be used. Proper installation and selection based on the medium they will seal can drastically affect performance and longevity.

**Tips:** Regularly monitoring the condition of your gasket sheets can lead to early detection of wear and potential failures. Additionally, consider investing in quality training for staff to ensure correct installation, as improper fitting is often a primary cause of gasket failure and can negate cost savings. By prioritizing these practices, organizations can fully leverage the cost efficiency of graphite gasket sheets in their operations.

Top 10 Benefits of Graphite Gasket Sheets You Should Know About - Cost Efficiency: Long-Term Savings with Graphite Gasket Sheets

| Benefit | Description | Long-Term Savings Potential |

|---|---|---|

| Durability | Graphite gasket sheets resist wear and tear, reducing the frequency of replacements. | High |

| Chemical Resistance | They withstand aggressive chemicals, ensuring integrity over time. | Medium |

| Temperature Tolerance | Suitable for high-temperature applications, maintaining performance. | High |

| Reduced Downtime | Less frequent maintenance and quicker installations lead to operational efficiency. | High |

| Versatility | Applicable in various industrial settings, thus reducing the need for multiple gasket types. | Medium |

| Lower Installation Costs | Simplified installation processes save labor costs. | Medium |

| Improved Sealing | Highly effective sealing properties prevent leaks and loss of materials. | High |

| Cost-Effectiveness | Although the initial investment can be higher, long-term savings are significant. | High |

| Environmental Resistance | Good performance in various environmental conditions adds to longevity. | Medium |

| Enhanced Performance | Effectively reduces energy loss in systems, promoting overall efficiency. | High |

Improved Seal Integrity and Performance Metrics of Graphite Gasket Sheets

Graphite gasket sheets have earned a reputation for their exceptional seal integrity in a variety of industrial applications. Their unique structure allows for excellent compression recovery, enabling them to maintain a tight seal even under fluctuating pressure and temperature conditions. This adaptability not only prevents leakage but also contributes to prolonged equipment life and enhanced operational efficiency. With their excellent thermal conductivity and resistance to both chemical attack and thermal degradation, graphite gaskets excel in high-performance environments, ensuring that seals remain intact and effective.

Moreover, the performance metrics of graphite gasket sheets highlight their ability to withstand harsh operating conditions without compromising integrity. They can accommodate the thermal expansion and contraction typically experienced in machinery, maintaining a robust seal throughout these changes. Their flexibility allows for easy installation and adaptation to various flange designs, which further cements their role as an essential component in numerous engineering projects. Utilizing graphite gasket sheets ensures a reliable sealing solution that minimizes downtime and enhances overall productivity in performance-driven industries.

Environmental Impact and Recyclability of Graphite Gasket Materials

The environmental impact of materials used in manufacturing is a growing concern, and graphite gasket sheets are no exception. Graphite, being a naturally occurring mineral, is favored for its durability and resistance to high temperatures and pressures. When it comes to recyclability, graphite gaskets are advantageous because they can be reprocessed and reused in various applications. This property not only reduces waste but also minimizes the need for virgin materials, thereby lowering the overall carbon footprint associated with their production.

Furthermore, the extraction and processing of graphite can be managed in an environmentally responsible way. Advances in mining technology and sustainable practices have led to reduced ecological disturbances. As industries increasingly seek to adopt greener practices, the use of recyclable materials like graphite gaskets aligns with broader sustainability goals. Their longevity and effectiveness reduce the frequency of replacements, which contributes to conservation efforts by lowering resource consumption over time. This ensures that graphite gasket sheets are not just an efficient choice but also an environmentally friendly option for sealing applications.

Related Posts

-

Maximizing Value with Best Flexible Graphite Gaskets: After-Sales Support and Maintenance Cost Insights for a Sustainable Future

-

Real-World Applications of the Best Graphite Gasket Sheet in Various Industries

-

Exploring Future Innovations in Best Flexible Graphite Gasket Technology for 2025

-

Exploring Innovative Alternatives to Graphite Gasket Sheets for Diverse Applications

-

How to Choose the Right Flexible Graphite Packing for Your Applications

-

7 Essential Tips for Choosing the Perfect Graphite Gasket Sheet for Your Needs