Top 5 Benefits of Using Graphite Cooling Film in Electronics

In the fast-evolving landscape of electronics, effective thermal management is paramount to ensuring device reliability and performance. The increasing demand for compact and high-performance electronic components has led to innovative cooling solutions that maintain optimal operating temperatures. Among these solutions, Graphite Cooling Film has emerged as a frontrunner due to its impressive thermal conductivity and lightweight properties. According to a report by MarketsandMarkets, the global thermal management market is expected to grow from USD 12.95 billion in 2020 to USD 23.24 billion by 2026, highlighting the critical role of advanced materials like Graphite Cooling Film in enhancing thermal performance across various applications.

Graphite Cooling Film not only addresses the challenges posed by escalating thermal loads in devices but also contributes to energy efficiency and reliability. Its exceptional ability to dissipate heat allows electronic components to function optimally, reducing the risk of thermal failure that can lead to downtime and damage. With a thermal conductivity that can exceed 1500 W/mK, Graphite Cooling Film outperforms traditional cooling methods, making it an essential material in the design of modern electronics. As the industry continues to pivot towards miniaturization and higher power densities, the adoption of efficient cooling technologies like Graphite Cooling Film will be crucial in supporting the sustainability and performance of electronic devices in the future.

Benefits of Enhanced Thermal Conductivity in Electronics

The integration of graphite cooling film in electronics presents significant advantages, particularly through its enhanced thermal conductivity. Research indicates that materials with high thermal conductivity can effectively dissipate heat, thereby preventing overheating—one of the leading causes of electronic component failure. According to a report by Research and Markets, the global thermal management market is projected to reach $26.8 billion by 2027, driven largely by the demand for efficient heat dissipation solutions in consumer electronics and data centers. Graphite cooling films, with thermal conductivity levels exceeding 1000 W/mK, are proving to be a game-changer in maintaining optimal operating temperatures for modern devices.

Additionally, the lightweight nature of graphite cooling films contributes to overall device performance. Traditional cooling methods, such as heavy metallic heatsinks, can add significant weight and bulk to electronics, compromising portability and design aesthetics. A study published in the Journal of Electronic Materials highlights that by incorporating graphite cooling films, manufacturers can reduce thermal interface materials by up to 30%, leading to slimmer designs without sacrificing thermal performance. This balance of efficiency and form factor is becoming increasingly crucial in today’s tech industry, where every millimeter of space counts in design specifications. Thus, the adoption of graphite cooling films not only enhances thermal management capabilities but also aligns with the industry's movement toward sleeker and more efficient electronic devices.

Improved Device Longevity through Efficient Heat Dissipation

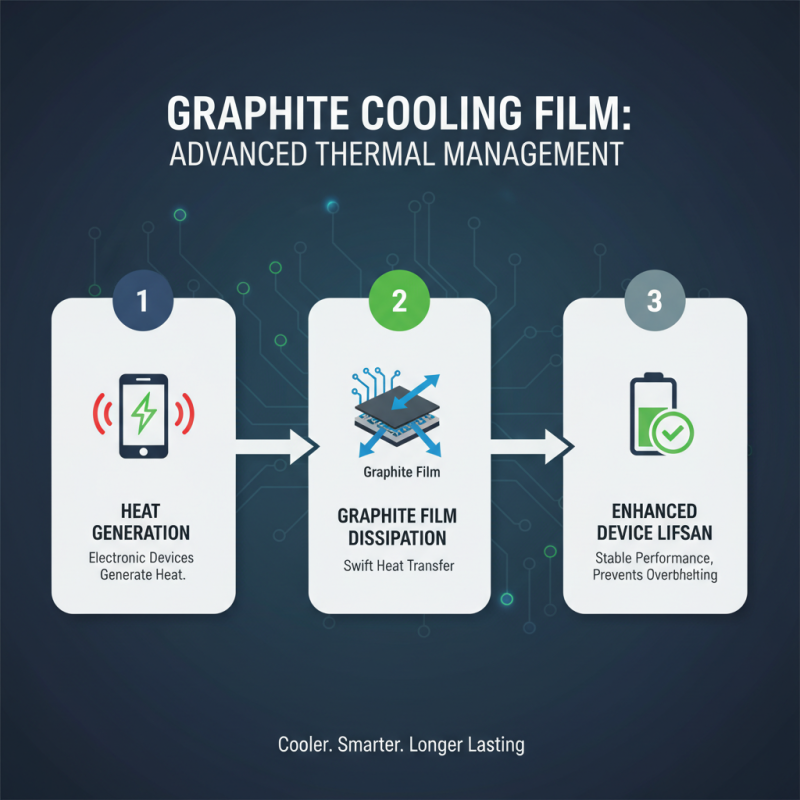

The integration of graphite cooling film in electronic devices marks a significant advancement in thermal management technologies. By efficiently dissipating heat generated during operation, these films extend the lifespan of various electronic components. Heat buildup can lead to performance degradation and eventual failure; however, graphite's high thermal conductivity allows for swift heat transfer away from critical areas. This proactive approach to thermal management not only maintains optimal operating temperatures but also reduces the likelihood of overheating, a common culprit in device malfunction.

In addition to prolonging device longevity, the use of graphite cooling films enhances overall efficiency and reliability. As electronic devices continue to become more powerful, effective heat dissipation methods are essential to ensure consistent performance. By minimizing thermal resistance, graphite films help devices maintain their functionality over extended periods, thus optimizing energy consumption and performance output. Ultimately, incorporating graphite cooling films in electronic systems paves the way for more durable technologies that cater to the ever-increasing demands of modern electronics.

Reduction of Overheating Risks with Graphite Cooling Films

Graphite cooling films have emerged as a crucial component in the electronics industry, particularly in mitigating the risks associated with overheating. As electronic devices become increasingly compact and powerful, the heat generated during their operation can lead to performance degradation and potential failure. Graphite's exceptional thermal conductivity allows for efficient heat dissipation, ensuring that critical components remain within optimal operating temperatures. This reduction of overheating risks not only prolongs the lifespan of electronic devices but also enhances reliability and performance.

To make the most out of graphite cooling films, consider proper application techniques. Ensure that the surface is clean and free from any contaminants before installation, as this can significantly affect the film's thermal interface. Additionally, integrating the cooling film in areas of high heat generation, such as near processors or power components, will maximize its effectiveness.

Moreover, regularly monitoring the temperature of your devices can help you determine if the graphite cooling film is performing as intended. If you notice any unusual temperature spikes, it may be time to reassess the film's condition or coverage. Utilizing heat sinks in combination with graphite films can further optimize heat management, pushing the efficiency of your electronics to new heights.

Top 5 Benefits of Using Graphite Cooling Film in Electronics

| Benefit | Description | Impact on Electronics |

|---|---|---|

| 1. Enhanced Thermal Management | Graphite cooling films efficiently dissipate heat, preventing component damage. | Increased lifespan of electronic devices. |

| 2. Lightweight and Thin Profile | Graphite films offer a high thermal conductivity in a minimal thickness. | Ideal for compact designs, enhancing portability. |

| 3. Flexible and Versatile Application | Can be applied to various surfaces and shapes in electronics. | Versatility in design integration. |

| 4. Cost-Effective Cooling Solution | Reduces the use of bulky heatsinks and complex cooling systems. | Saves on overall manufacturing costs. |

| 5. Environmentally Friendly | Made from natural graphite, contributing to sustainability. | Appeals to eco-conscious consumers and manufacturers. |

Increased Performance and Efficiency of Electronic Components

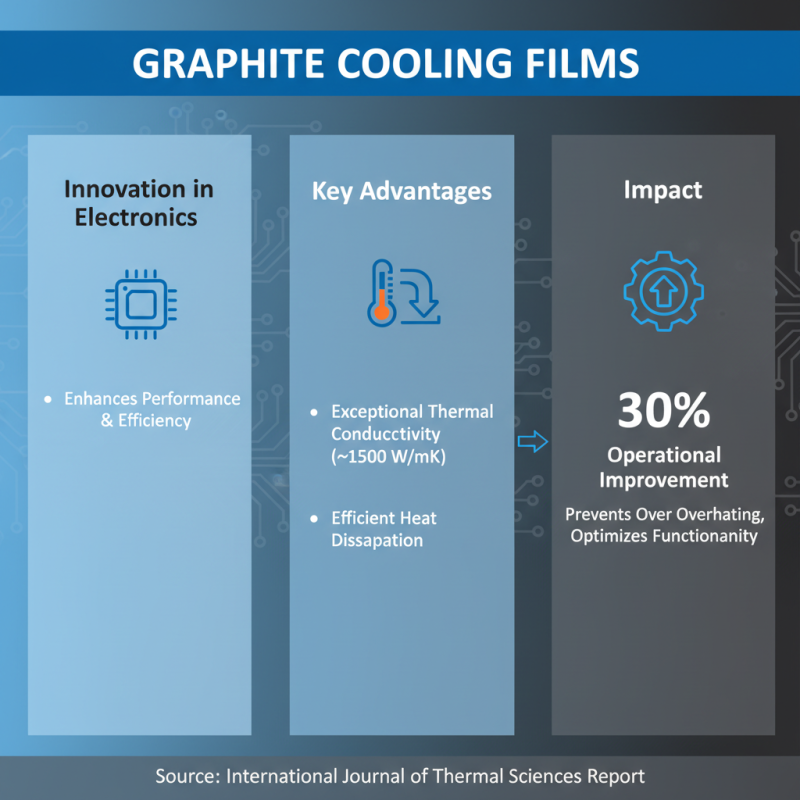

Graphite cooling films have emerged as a crucial innovation in the realm of electronics, significantly enhancing the performance and efficiency of electronic components. According to a recent industry report by the International Journal of Thermal Sciences, devices that utilize advanced thermal management solutions, such as graphite cooling films, can achieve operational improvements of up to 30%. This is largely due to graphite's exceptional thermal conductivity, which can reach values around 1500 W/mK, allowing for efficient heat dissipation that prevents overheating and optimizes component functionality.

Moreover, the integration of graphite cooling films results in a reduction in energy consumption by approximately 20%, as evidenced by a study published by the Electronics Cooling Association. This energy efficiency not only leads to cost savings over time but also contributes to sustainability efforts within the electronics sector by minimizing the carbon footprint associated with energy usage. By enhancing performance while reducing the heat load on components, graphite cooling films offer a dual advantage, ensuring that electronic devices operate at peak efficiency without compromising on thermal management. These benefits solidify graphite as a key player in advancing the future of electronic component design and application.

Cost-Effectiveness and Sustainability of Graphite Cooling Solutions

The adoption of graphite cooling film in electronics offers a remarkable approach to addressing thermal management while emphasizing cost-effectiveness and sustainability. This innovative material provides exceptional thermal conductivity, which enhances heat dissipation in electronic devices, thereby potentially extending their lifespan and improving performance. Unlike traditional cooling methods that often rely on complex systems or high-energy-consuming components, graphite cooling solutions reduce the need for excessive materials and energy usage, resulting in lower overall production costs.

Moreover, the sustainability aspect of graphite cooling film cannot be overstated. Graphite is a naturally occurring material that can be sourced responsibly, contributing to a more eco-friendly manufacturing process. Its durability also ensures longevity, reducing waste from frequent replacements that are common with less sustainable cooling solutions. By embracing graphite as a cooling medium, manufacturers can lower their carbon footprint while delivering efficient performance, aligning with both economic and environmental objectives in the electronics industry. This strategic move not only proves beneficial for electronic components but also supports broader initiatives for sustainable development.

Top 5 Benefits of Using Graphite Cooling Film in Electronics

Related Posts

-

Top 10 Thermal Graphite Sheet Manufacturers from China at the 137th Canton Fair

-

Ultimate Guide to Sourcing Thermal Graphite Sheets for Enhanced Thermal Management Solutions

-

What is Flexible Graphite Sheet and How It Revolutionizes Industrial Applications?

-

Exploring Market Trends: Thermal Graphite Sheets at the 138th Canton Fair 2025 in China

-

Understanding the Advantages of Flexible Graphite Sheet in High Temperature Applications

-

Understanding the Role of Graphite Thermal Film in Modern Electronics