What Are the Benefits of Flexible Graphite Gaskets?

Flexible Graphite Gaskets are versatile sealing solutions used in various industries. These gaskets are made from high-quality graphite, providing excellent resistance to harsh environments. They can withstand extreme temperatures and pressures, making them ideal for applications in chemical processing and power generation.

One of the main benefits of Flexible Graphite Gaskets is their adaptability. They can conform to irregular surfaces, ensuring a tight seal. This adaptability can be a double-edged sword; improper installation may lead to leaks. Therefore, attention to detail is crucial during the installation process.

Another advantage is the gasket's longevity. Unlike traditional gaskets, they resist wear and tear over time. However, users should remain vigilant. Conditions such as chemical exposure might still affect performance. Overall, Flexible Graphite Gaskets offer significant benefits but require careful handling and installation to ensure optimal performance.

Benefits of Flexible Graphite Gaskets in Industrial Applications

Flexible graphite gaskets are essential in various industrial applications. They provide excellent sealing solutions under high temperatures and pressures. This material is known for its durability and resilience. It can withstand extreme environments, making it suitable for many industries.

In many cases, these gaskets help reduce maintenance costs. Their long lifespan means less frequent replacements. However, improper installation can lead to failures. It’s crucial to follow installation guidelines to ensure effectiveness.

**Tips:** Always inspect the gasket surface for debris before sealing. This simple step can prevent leaks. Additionally, consider the temperature and pressure ratings carefully. Mismatching these can lead to serious issues down the line.

Moreover, flexible graphite gaskets are chemical-resistant. They can handle various substances, making them versatile. However, not all graphite gaskets are created equal. Some may not perform well in specific chemicals. Always consult material data sheets for guidance.

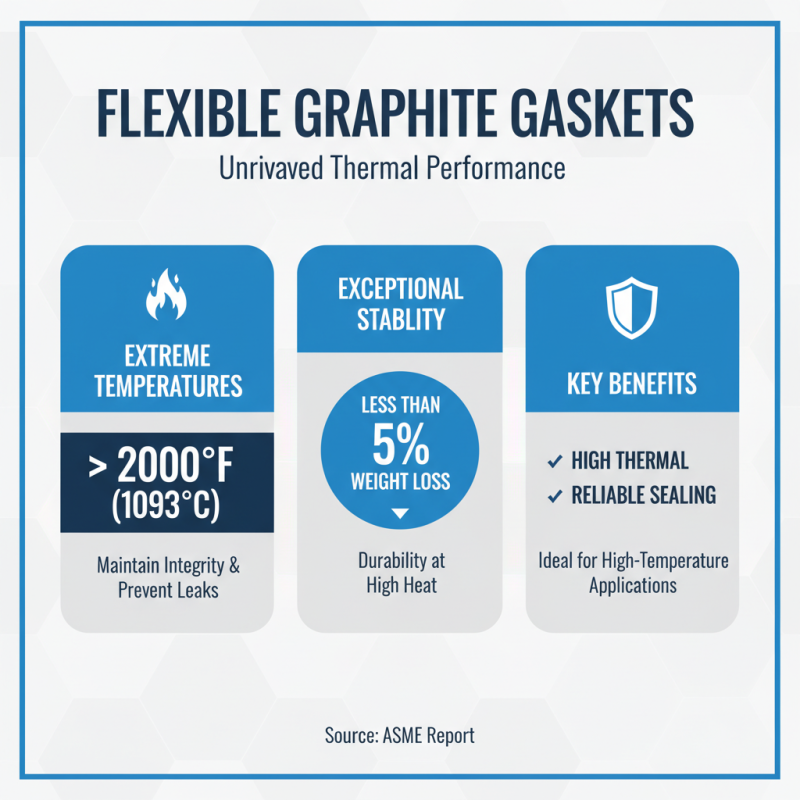

Thermal Resistance and Stability of Flexible Graphite Gaskets

Flexible graphite gaskets boast impressive thermal resistance and stability, making them indispensable in high-temperature applications. These gaskets can withstand extreme temperatures exceeding 2000°F (1093°C), maintaining their integrity while preventing leaks. A report by the American Society of Mechanical Engineers highlights that flexible graphite shows less than 5% weight loss at these temperatures, proving its durability.

Manufacturers are increasingly opting for flexible graphite gaskets due to their stability. Unlike traditional materials, flexible graphite can handle thermal cycling without degrading. The material's ability to expand and contract prevents compression set, a common failure point in gaskets. This stability translates directly into reliability and longevity, reducing maintenance costs.

Tips: Always consider gasket application temperature ranges. This ensures optimal performance. Review installation procedures regularly to avoid leakage issues. Proper handling and storage of gaskets are also essential. Avoid exposing gaskets to ambient turbulence, as this can lead to premature failure.

Chemical Compatibility of Flexible Graphite Gaskets Explained

Flexible graphite gaskets are known for their impressive chemical compatibility. Their unique structure forms a barrier against many aggressive substances. This makes them suitable for various industrial applications, from chemical processing to power generation. Flexible graphite can withstand extreme temperatures and pressures. That's a crucial advantage in demanding environments.

Tips: Always check compatibility charts before selection. Not all graphite types behave the same. Keep in mind, improper use can lead to failure.

In some cases, the material may degrade over time. This depends on the specific chemicals it encounters. While flexible graphite shows resilience, some aggressive solvents can still affect its integrity. Regular inspections are essential to ensure optimal performance.

Tips: Schedule routine checks. Identify any wear or leakage early. Don’t assume all gaskets will last indefinitely. Each application can reveal different challenges.

Installation and Maintenance Advantages of Flexible Graphite Gaskets

Flexible graphite gaskets offer distinct installation and maintenance advantages. Their flexibility allows for easy adaptation to uneven surfaces. This characteristic is crucial in ensuring a reliable seal in various environments. According to a 2021 industry report, a significant percentage of leaks in industrial applications stem from improper gasket installation. Flexible graphite gaskets can reduce this risk.

Another advantage is their resistance to extreme temperatures and chemicals. A study from the 2022 Gasket Technology Conference showed that these gaskets maintained integrity in conditions ranging from -200°C to +450°C. This durability minimizes the frequency of maintenance checks. However, care must be taken; improper handling can compromise their effectiveness. Users should be aware of the proper installation techniques to maximize performance.

Despite these benefits, the inevitable wear and tear should not be overlooked. Over time, even high-quality gaskets can degrade. Regular inspections are necessary to ensure ongoing effectiveness. Industry professionals emphasize the importance of a proactive maintenance schedule. This approach helps identify potential issues before they escalate, ensuring that systems run smoothly.

Cost-Effectiveness and Longevity of Flexible Graphite Gaskets

Flexible graphite gaskets are versatile solutions for various industrial applications. They offer significant cost-effectiveness compared to traditional gasket materials. According to a recent industry report, users can expect up to 30% savings on maintenance costs when opting for flexible graphite gaskets. Their durability and heat resistance contribute to lower replacement frequency.

However, these gaskets may not always be the best fit for every situation. Their effectiveness can diminish under extreme conditions. This leads to potential leak issues, which in turn incurs additional costs. It's essential to assess application requirements before selection.

Tips: Always consider your operational environment. Testing performance in real conditions can reveal hidden challenges. Regular inspections can further ensure longevity. Ignoring maintenance could lead to costly failures over time. Balancing cost-effectiveness and performance is crucial for optimal results.

Related Posts

-

Top 5 Benefits of Using Flexible Graphite Gaskets for Industrial Applications

-

Real-World Applications of the Best Graphite Gasket Sheet in Various Industries

-

Maximizing Value with Best Flexible Graphite Gaskets: After-Sales Support and Maintenance Cost Insights for a Sustainable Future

-

Top 10 Benefits of Using Natural Graphite Sheet for Your Applications

-

What Makes Graphite Sheets the Ideal Choice for Industrial Applications

-

Leading Graphite Sheet Manufacturer in China Delivering Export Quality to the Global Market