Top 10 Benefits of Flexible Graphite for Industrial Applications?

Flexible graphite has become a crucial material in various industrial applications. Experts emphasize its versatility and resilience. Dr. Emily Carter, a leading scientist in the field, states, "Flexible graphite is revolutionizing how we approach industrial solutions." Her words resonate with the growing demand for this innovative material.

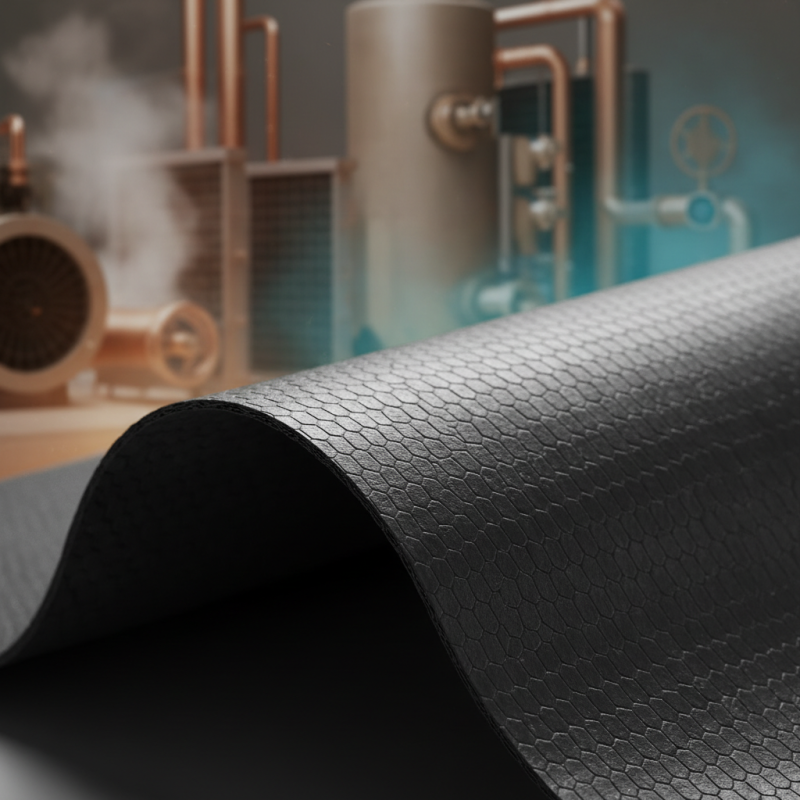

Manufacturers are increasingly turning to flexible graphite due to its unique properties. It offers excellent thermal and chemical resistance. This material can withstand extreme temperatures and harsh environments. Yet, many still question its long-term performance in critical applications.

The advantages are clear, but challenges remain. Industries must continue to explore the best ways to integrate flexible graphite. As technology evolves, so will the applications of this remarkable material. The journey is ongoing, and reflections on its effectiveness are essential.

Key Properties of Flexible Graphite in Industrial Use

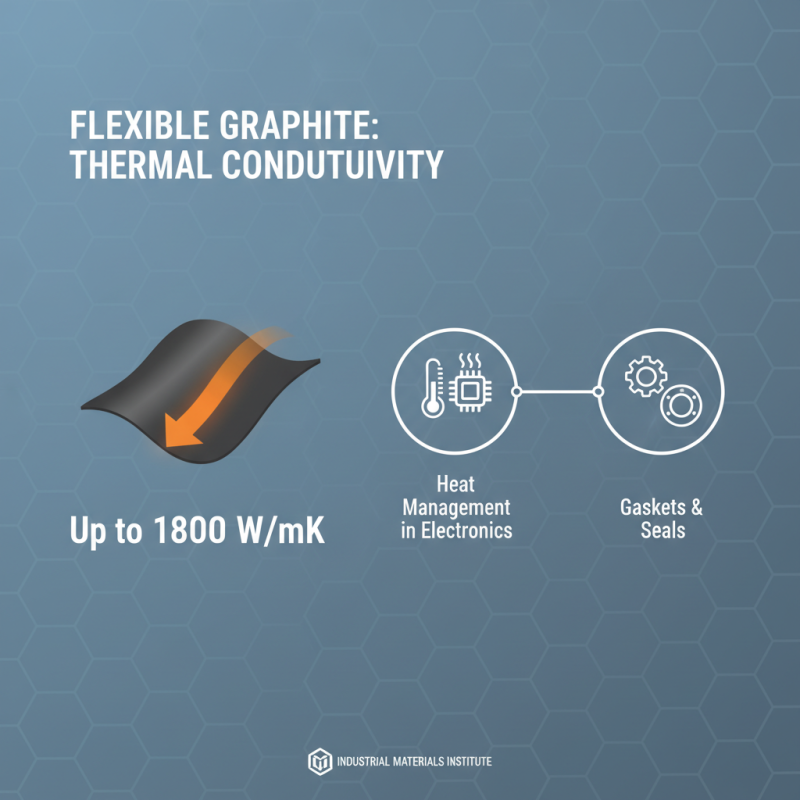

Flexible graphite is increasingly popular in various industrial applications due to its unique properties. Its outstanding thermal conductivity makes it ideal for heat management. A recent report by the Industrial Materials Institute indicated that flexible graphite has thermal conductivity values up to 1,800 W/mK. Such performance ensures efficient heat dissipation in applications like gaskets and seals.

Additionally, flexible graphite showcases remarkable corrosion resistance. It can withstand aggressive chemicals commonly found in industrial settings. This property significantly extends the lifespan of components, leading to cost savings. Studies have suggested that components made with flexible graphite can last 30% longer than those made with traditional materials. However, sourcing flexible graphite can be challenging. Quality control during manufacture is essential to ensure consistent performance.

Moreover, flexible graphite's compressibility and resilience provide excellent sealing capabilities. It conforms well to irregular surfaces, ensuring minimal leakage. According to various industry reports, improper sealing can lead to energy losses of up to 30%. However, there's still debate on its long-term durability under extreme conditions. Some experts call for more extensive research to fully understand its limitations. These considerations highlight the need for continuous innovation in materials science.

Enhanced Thermal Conductivity of Flexible Graphite

Flexible graphite shows remarkable thermal conductivity, making it ideal for various industrial applications. This property allows it to effectively transfer heat, ensuring optimal performance in high-temperature environments. Industries such as aerospace, automotive, and energy benefit greatly from this characteristic. The ability to maintain structure under stress gives flexible graphite an edge over traditional materials.

When choosing flexible graphite, consider its density and thickness. Thicker materials often provide better insulation, while thinner sheets enable more efficient heat transfer. If you require flexibility, pay attention to these factors. Proper selection can enhance performance in critical applications.

Remember, not all flexible graphite products are created equal. Quality may vary, impacting thermal conductivity. Conduct thorough research before making decisions. Always verify your sources. Flexible graphite can transform industrial processes, but ensure it meets your specific needs for best results.

Chemical Resistance Advantages of Flexible Graphite

Flexible graphite offers notable chemical resistance, making it ideal for various industrial applications. This material can withstand extreme temperatures and harsh chemicals. It resists acids, alkalis, and solvents effectively. In environments where materials face aggressive substances, flexible graphite performs reliably. It won't easily degrade, ensuring longevity.

Another key advantage is its adaptability. Flexible graphite can conform to different shapes and sizes. This property enhances sealing performance in pumps and valves. By creating tight seals, it reduces leakage risks, improving overall system efficiency. Additionally, it is lightweight. This characteristic makes handling easier and reduces installation challenges.

However, it is essential to consider its limitations. While flexible graphite is durable, improper handling can lead to quality issues. Minor imperfections during installation may affect performance. A careful approach in using this material is crucial for optimal results. Each application demands a thoughtful assessment of flexible graphite's benefits and drawbacks.

Versatility in Applications: From Seals to Gaskets

Flexible graphite is a remarkable material that finds extensive use in various industrial applications. Its versatility enables it to serve multiple functions, particularly in seals and gaskets. Manufacturers appreciate how flexible graphite can accommodate extreme temperatures and pressures. This adaptability ensures optimal performance in challenging environments, which is often crucial for equipment longevity.

Seals and gaskets are essential to prevent leaks in machinery. Flexible graphite's unique structure creates a reliable barrier against fluids and gases. The material’s inherent flexibility allows it to conform to uneven surfaces, ensuring a tighter seal. However, achieving the perfect fit can sometimes be challenging. Installation must be done with care to maximize its effectiveness, which may require some trial and error.

In the field of energy production, the demand for efficient sealing solutions continues to grow. Flexible graphite has shown promise in both renewable and fossil fuel applications. Its ability to withstand harsh chemicals is a significant benefit. Still, users must remain vigilant about routine inspections. Over time, wear and tear can compromise performance, making regular maintenance a key consideration.

Top 10 Benefits of Flexible Graphite for Industrial Applications

| Benefit | Description | Industrial Applications |

|---|---|---|

| High Temperature Resistance | Can withstand extreme temperatures without degrading. | Used in furnace seals and heat exchangers. |

| Chemical Resistance | Resistant to a wide range of chemicals and solvents. | Applicable in chemical processing and petrochemical industries. |

| Flexibility | Can be easily shaped to fit various applications. | Ideal for gaskets and seals in irregular surfaces. |

| Low Thermal Conductivity | Excellent thermal insulator. | Used in thermal barriers and insulating materials. |

| Durability | Long-lasting and resistant to wear and tear. | Applied in automotive and aerospace components. |

| Lightweight | Reduces overall weight without compromising strength. | Used in lightweight machinery and transport applications. |

| Cost-Effectiveness | Reduces maintenance costs due to longevity. | Utilized across various industries to reduce operational costs. |

| Non-Toxic | Safe for use in food and pharmaceutical applications. | Applicable in food processing and cleanroom environments. |

| Electrical Conductivity | Good conductor of electricity, useful in specific applications. | Used in electrical components and connections. |

| Customizable | Can be manufactured in various forms and dimensions. | Used in tailored solutions for specific industrial needs. |

Cost-Effectiveness and Longevity of Flexible Graphite Solutions

Flexible graphite has become a go-to material for many industries. Its unique properties make it cost-effective and long-lasting. Industries rely on flexible graphite for gaskets, seals, and more. This versatile material is resistant to high temperatures and chemicals. It often lasts longer than traditional materials, reducing the need for frequent replacements.

The cost-effectiveness of flexible graphite solutions is noteworthy. Businesses can save significantly on replacement and maintenance costs. However, some may underestimate its initial investment. A thoughtful analysis is required to gauge long-term savings. Flexible graphite performs well under pressure, but it isn’t without its challenges. Some applications may require adjustments for optimal performance.

Longevity is a double-edged sword. While flexible graphite lasts longer, it can be viewed as less flexible in certain environments. Companies must assess their specific needs. In some cases, a different material might serve better. The advantages are clear, but understanding the limitations is essential. Balancing cost and performance can be tricky, yet it's a worthwhile endeavor for many.

Related Posts

-

What Makes Graphite Sheets the Ideal Choice for Industrial Applications

-

7 Essential Tips for Choosing the Perfect Graphite Gasket Sheet for Your Needs

-

Top 10 Benefits of Using Natural Graphite Sheet for Your Applications

-

Exploring Unique Alternatives to Best Graphite Paper Staples for Your Crafting Needs

-

2025 Top 10 Graphite Carbon Paper Options for Every Artist and Printer

-

Overcoming the Challenges of Using Best Graphite Paper Officeworks in Your Projects